Venting a Macerating Toilet

tradertom

15 years ago

Related Stories

HOME TECHMeet the New Super Toilets

With features you never knew you needed, these toilets may make it hard to go back to standard commodes

Full Story

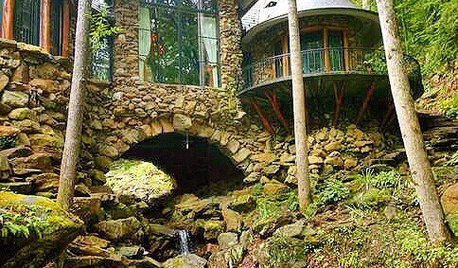

BASEMENTSTricky Basement Bathroom? Cool Design Opportunity!

Have some fun with your bathroom design while getting all the venting, privacy and storage you need

Full Story

BATHROOM DESIGNRoom of the Day: Master Bath Wears Its Elegance Lightly

This dream ‘hers’ bathroom includes a soaking tub, shower, sauna and toilet room — and a fun vintage movie poster

Full Story

BATHROOM DESIGNSee the Clever Tricks That Opened Up This Master Bathroom

A recessed toilet paper holder and cabinets, diagonal large-format tiles, frameless glass and more helped maximize every inch of the space

Full Story

KITCHEN DESIGNAutomation Meets Innovation in the Newest Kitchen and Bath Products

Home features from closets to toilets are going touchless, remote controlled and more accessible than ever. See for yourself

Full Story

FUN HOUZZTechnicolor Solutions to 3 Popular Home Peeves

Imagination runs wild in these illustrated solutions for Houzzers' home dilemmas

Full Story

GREEN BUILDINGWater Sense for Big Savings

Keep dollars in your pocket and preserve a precious resource with these easy DIY strategies

Full Story

FUN HOUZZ14 Things You Need to Start Doing Now for Your Spouse’s Sake

You have no idea how annoying your habits at home can be. We’re here to tell you

Full Story

FUN HOUZZ31 True Tales of Remodeling Gone Wild

Drugs, sex, excess — the home design industry is rife with stories that will blow your mind, or at least leave you scratching your head

Full Story

KITCHEN APPLIANCESLove to Cook? You Need a Fan. Find the Right Kind for You

Don't send budget dollars up in smoke when you need new kitchen ventilation. Here are 9 top types to consider

Full Story

lazypup

tradertomOriginal Author

Related Discussions

macerating toilet experiences

Q

Saniflo Macerating toilet?

Q

Macerating toilet for new custom built home

Q

I can wet vent my toilet vent... right?

Q

lazypup

Altamirano LLC

Vanetta