Fisher Paykel GWL11 diverter valve always off, bad controller? Again?

northbear

7 years ago

Related Stories

REMODELING GUIDES7 Bad Things Your Home May Be Hiding

What you don't know about your home could cost you during a remodel. Here's what to plan for

Full Story

SAVING WATER11 Ways to Save Water at Home

Whether you live in a drought-stricken area or just want to help preserve a precious resource, here are things you can do to use less water

Full Story

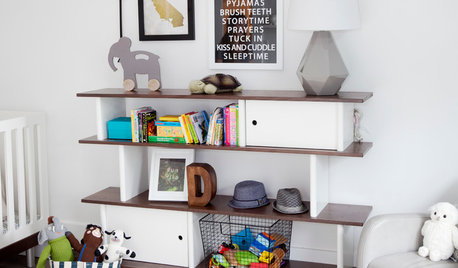

KIDS’ SPACES15 Tips for Small-Space Living With Baby

Keep your wee one's stuff under control and your nerves unfrazzled with these space-saving storage and baby-gear ideas

Full Story

UNIVERSAL DESIGN11 Ways to Age-Proof Your Bathroom

Learn how to create a safe and accessible bathroom without sacrificing style

Full Story

REMODELING GUIDESSurvive Your Home Remodel: 11 Must-Ask Questions

Plan ahead to keep minor hassles from turning into major headaches during an extensive renovation

Full Story

LIFE7 Things to Do Before You Move Into a New House

Get life in a new house off to a great start with fresh paint and switch plates, new locks, a deep cleaning — and something on those windows

Full Story

BATHROOM DESIGNConvert Your Tub Space to a Shower — the Fixtures-Shopping Phase

Step 2 in swapping your tub for a sleek new shower: Determine your mechanical needs and buy quality fixtures

Full Story

HOUZZ TOURSMy Houzz: Industrial-Edged Comfort in Pittsburgh

Copper, cantilevers and a cat named Mr. Martin come together in this contemporary homage to regional style

Full Story

GREAT HOME PROJECTS25 Great Home Projects and What They Cost

Get the closet of your dreams, add a secret doorway and more. Learn the ins and outs of projects that will make your home better

Full Story

BATHROOM DESIGN18 Dream Items to Punch Up a Master-Bath Wish List

A designer shared features she'd love to include in her own bathroom remodel. Houzz readers responded with their top amenities. Take a look

Full Story

dadoes

northbearOriginal Author

Related Discussions

Fisher Paykel GWL11 not filling in rinse cycle

Q

Fisher and Paykel GWL11 Top Loading Washer

Q

Fisher Paykell GWL11 stuck in code 49

Q

Fisher Paykel GWL11 short circuit

Q

Rick Brown

northbearOriginal Author