Why I won't use Vinyl

goinggreen2008

15 years ago

Featured Answer

Sort by:Oldest

Comments (11)

Michael

15 years agolast modified: 9 years agoRelated Discussions

Why I won't be doing any gardening until Thu

Comments (13)What a little doll!! When I was 63, my son and 3 kids moved in with us in our little 1500 sq ft home with about 3 days notice, ages 2, 5 and 8; I was working full time; two of the kids are autistic. We hardly knew each other, and you talk about culture shock! They stayed for five years until my son remarried and moved out. I don't like kids, remember, and SOMEONE was teaching me a lesson for that!! We're all fortunate that they're highly intelligent, and I look back on those years with such fond memories and learned so much... Monday night was spaghetti night with table cloth and candles, and even now when they come over we have to have that!...See MoreWhy I won't buy a Bosch appliance again

Comments (13)Thank you for your responses. It is so reassuring to have that support. I will write to the company CEO when this is all over and will print out all your comments for his edification! Thank you for the address,Tracey's. I went over the warranty terms with great care yesterday (after the most recent customer sevice rep kept asking me whether I had read the warranty, presumably suggesting that I should not be bothering him with questions about the warranty). The salient points appear to be: 1. There is a 365 day warranty (beware leap years!) 2. Starting on the date of purchase (I am not sure what that date is. Is it the date of delivery? Or the date of payment or financing arrangements being made? Or the date the order is placed?) 3. There is no extension "for any reason whatsoever" of this warranty (i.e. if the problem arises on day 364 and the repair hasn't been made by day 365, you are out of luck.) 4. Replacement parts don't get a warranty extension either. 5. There is no warranty at all for a range which is sold as a store display or is sold "as is". 6. The warranty is automatically void if anyone other than an authorized service provider works on the range. Noone else is even permitted to explore "the appliance's inner workings." CAVEAT EMPTOR. Don't buy til you've studied the warranty...See MoreWhy Won't Anyone Fix Windows, Only Replace?

Comments (11)Totally agree with the "desappear" problem. I still wouldn't be worried about him falling if you had correct coverage. I have had 4 roofs replaced due to hail, and a 4 car garage burn up. None of these items have affected my rates. Sorry if I came off harsh, bad thing about internet is you cant tell ones tone. Still am curious if a guy needs to be bonded. I have never checked this and am curious why I should. I have checked this with property managers where they were collecting my rents and holding them for a month. ANYWAY I believe people don't repair windows as its not a big money maker. I have fixed a few things on double hung windows and you never know what you are getting into untill after you've started. I would say to repair a window is almost the same amount of labor as installing a new window. The new window allows the company to profit on labor and materials. So for it to be cost effective I would guess the window company would actually have to charge more labor for fixing a window than installing one. Other thing my window installer friend said is old windows just aren't as efficent as new ones and its just a good idea to replace if working or not. Good Luck!...See MoreWhy oh why won't the city issue me a permit to start work???

Comments (4)I feel your pain! I've worked with our architect for over 16 months before we pulled our building permits. We're converting our 1825 2 family back into a single family, gutting the kitchen and 2 baths, adding 144 square feet to the kitchen, adding a half bath and adding a 78 sq. ft. mud room. My contractor was going to pull the permit on a Wed and asked on Fri - did you sign the tree permit? I was not familiar with THAT permit and went down to city hall to get it on Mon. Since I was going to be at inspectional services anyway I decided to run my plans by the inspector. (Also, one big reason I picked my architect and contractor is that they do most of their work in our town). In our town (Newton, MA) about 15 different permits are needed. Everything was in order EXCEPT the board of alderman made an "oops" change in the zoning laws 2 months previous. Now 20% of the town's housing stock needs a special permit for any addition - even though it meets the other laws. We fell into that 20%. They said the special permit process has been "streamlined" and is "quick and doesn't cost any more than a regualar permit". It will take a minimum 4+ extra months, my neighbors all get to weigh in on my modest addition at a town public meeting and it will cost an additional $10,000! I have complained loudly. Also, once you get a special permit you have to have a special permit for any changes to the exterior including like removing a walkway, changing garage doors, etc. even though it meets all zoning codes. If you don't do exactly what's on the permit you have to change it. One guy didn't want to change his stairs and they sent him to jail (this was told to me by the special permit review board)! I haven't even started construction and have had so many headaches. In parallel I'm trying to get the alderman (24!) to make the correct changes to the zoning laws - this will allow me to procede smoothly. With summer and 24 of them this is a difficult task. I HATE town politics. We want to pour our cement before winter! Oh, did I mention I gave my tenants notice to move by last July 1st. Thank goodness they were our of town for a few weeks and didn't find anything. Oh, I did have my HVAC guy drain the 1st floor radiators so there's no heat (we're putting in central air in heat). Yes, I feel your pain!...See Moreafsa

15 years agolast modified: 9 years agohoneycombe8

8 years agosushipup1

8 years agokrypton

8 years agohoneycombe8

8 years agokrypton

8 years agolast modified: 8 years agoHomeSealed Exteriors, LLC

8 years agolast modified: 8 years agokrypton

8 years agolast modified: 8 years agoWindows on Washington Ltd

8 years ago

Related Stories

KIDS’ SPACES7 Kids’ Bedroom Decor Ideas That Won’t Break the Bank

Take an economical approach to decorating your child’s room with these DIY ideas

Full Story

SMALL SPACES10 Tiny Kitchens Whose Usefulness You Won't Believe

Ingenious solutions from simple tricks to high design make this roundup of small kitchens an inspiring sight to see

Full Story

FURNITURE12 Sofa Colors That Won't Box You In

With any of these colors as a base, you can change your decor as often as you change your mind

Full Story

ARCHITECTURE5 Homes That Won't Box You In

Unexpected architectural shapes outside create unique spaces inside these homes that respond strongly to their sites

Full Story

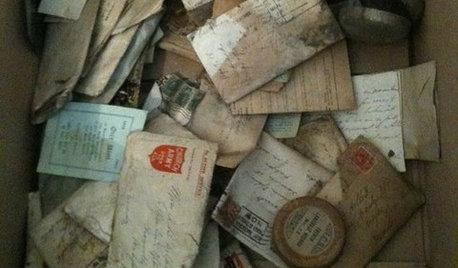

REMODELING GUIDESYou Won't Believe What These Homeowners Found in Their Walls

From the banal to the downright bizarre, these uncovered artifacts may get you wondering what may be hidden in your own home

Full Story

HOME TECH3 Kitchen Contraptions You Won’t Believe

Pizza hot from the printer, anyone? These cooking gadgets harness imagination and high tech — and have price tags to match

Full Story

BUDGET DECORATING15 Summery Decorating Ideas That Won't Break the Bank

Transport yourself seaside with a bit of paint or a few airy accessories

Full Story

SMALL SPACESHouzz TV: You Won’t Believe Everything This Tiny Loft Can Do

Looking for more floor space, a San Francisco couple hires architects to design a unit that includes beds, storage and workspace

Full Story

BATHROOM MAKEOVERS9 Powder Room Splurges You Won’t Regret

Make a big statement in your smallest room

Full Story

skydawggy