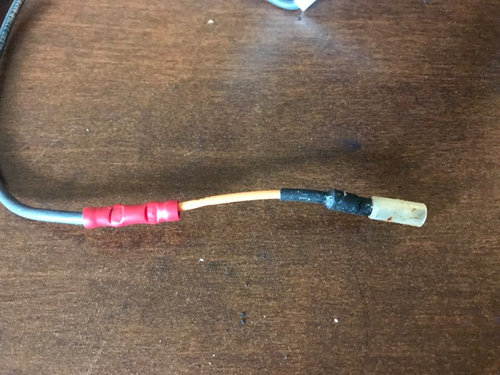

Bluestar range ignitor / igniter replacement....finally a solution

Matthew Rieger

4 years ago

last modified: 4 years ago

Related Stories

KITCHEN APPLIANCESDisappearing Range Hoods: A New Trend?

Concealed exhaust fans cut visual clutter in the kitchen

Full Story

KITCHEN DESIGNHow to Get Your Range Hood Right

Get a handle on the technical specs, and then learn about fun design options for creating a beautiful kitchen feature

Full Story

MOST POPULARBefore and After: 13 Dramatic Kitchen Transformations

See the wide range of ways in which homeowners are renovating their kitchens

Full Story

KITCHEN DESIGNShow Us Your Best Kitchen Innovation

Did you take kitchen functionality up a notch this year? We want to see your best solutions for the hardest-working room in the house

Full Story

KITCHEN APPLIANCESFind the Right Cooktop for Your Kitchen

For a kitchen setup with sizzle, deciding between gas and electric is only the first hurdle. This guide can help

Full Story

BATHROOM DESIGNTrending Now: The 20 Most Popular New Bathrooms of 2017

Smart storage, warm finishes, clear glass, tiled walls and other favorite bath details grew in popularity this year

Full Story

KITCHEN DESIGNA Cook’s 6 Tips for Buying Kitchen Appliances

An avid home chef answers tricky questions about choosing the right oven, stovetop, vent hood and more

Full Story

KITCHEN DESIGNSo Over Stainless in the Kitchen? 14 Reasons to Give In to Color

Colorful kitchen appliances are popular again, and now you've got more choices than ever. Which would you choose?

Full Story

KITCHEN APPLIANCESFind the Right Oven Arrangement for Your Kitchen

Have all the options for ovens, with or without cooktops and drawers, left you steamed? This guide will help you simmer down

Full Story

HOUSEKEEPING7-Day Plan: Get a Spotless, Beautifully Organized Garage

Stop fearing that dirty dumping ground and start using it as the streamlined garage you’ve been wanting

Full Story

Related Discussions

Bluestar - Finally an aftermarket ignitor

Q

Generic BlueStar range ceramic ignitors?

Q

Bluestar ignitor question

Q

bluestar 30' RCS oven ignition system

Q