Bending Copper Pipe II

solarpowered

18 years ago

Related Stories

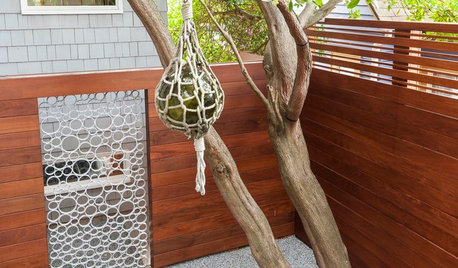

FENCES AND GATESA Designer Uses PVC Pipe to Cast a Modern Garden Gate

Landscape designer Scot Eckley walks us through the process of creating a custom aluminum ring gate

Full Story

KITCHEN DESIGNKitchen Sinks: Fireclay Brims With Heavy-Duty Character

Cured at fiery temperatures, fireclay makes for farmhouse sinks that just say no to scratches and dents

Full Story

KITCHEN DESIGNA Modern Kitchen Inspired by Edwardian Style

Attention to detail and functionality make for a kitchen that is as beautiful to work in as it is to look at

Full Story

MOST POPULARHow to Choose the Right Kitchen Sink

Learn about basin configurations, sink shapes, materials and even accessories and specialty sinks

Full Story

KITCHEN SINKSEverything You Need to Know About Farmhouse Sinks

They’re charming, homey, durable, elegant, functional and nostalgic. Those are just a few of the reasons they’re so popular

Full Story

GREAT HOME PROJECTSHow to Add a Skylight or Light Tube

New project for a new year: Increase daylight and maybe even your home’s energy efficiency by opening a room to the sky

Full Story

KITCHEN DESIGNKitchen Sinks: Granite Composite Offers Superior Durability

It beats out quartz composite for strength and scratch resistance. Could this kitchen sink material be right for you?

Full Story

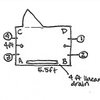

FARM YOUR YARDHow to Build a Raised Bed for Your Veggies and Plants

Whether you’re farming your parking strip or beautifying your backyard, a planting box you make yourself can come in mighty handy

Full Story

MOST POPULARHow to Start a Cool-Season Vegetable Garden

Late summer and late winter are good times to plan and plant cool-season crops like salad greens, spinach, beets, carrots and peas

Full Story

KITCHEN DESIGNStandouts From the 2014 Kitchen & Bath Industry Show

Check out the latest and greatest in sinks, ovens, countertop materials and more

Full Story

shacko

brickeyee

Related Discussions

best way to bend 3/4 copper pipe?

Q

Is there a way to bend pvc?

Q

Pin hole leaks in copper pipes

Q

90 degree long radius bend in 1' rigid copper?

Q

fixizin

pinocchio

fixizin

lazypup

brickeyee

pinocchio

lazypup

pinocchio

barb3073

lazypup

barb3073

brickeyee

sircuts_freeshell_org

brickeyee

shw001

pjb999

lazypup

shw001

pjb999