I wanted to open up a different discussion about vibration. It seems like many people are targeting the vibration issues by trying random methods without really understanding what they are trying to resolve.

First and foremost, what are you trying to solve? Is it REALLY vibration or is it just noise? Noise can be confused with vibration as many times upstairs laundry rooms are not designed to contain noise and sounds can be transmitted through solid objects extremely efficiently.

Vibration on the other hand is where the movement of the machine is causing your house structure to actually move and pick up a sympathetic vibration and the house itself makes noise (or the interaction between the unit and house). Generally low frequency, which can be hard to absorb and travels far.

The two have some similar solutions, but what might make one better can in fact make the other worse. This is especially true of the real vibration problem.

So lets start at the common wisdom solutions:

1: Strengthen the floor.

This is definitely a place where common wisdom can be a cause for failure. By strengthening the floor the idea is that you are going to stop your house from vibrating. Unfortunately this can backfire, especially if your problem is actually noise and not vibration.

When you strengthen the floor you are eliminating the ability for that section of flooring to move. For vibration this is good, because you are forcing the suspension in the unit to do more work and keep from building a sympathetic vibe in the floor that causes a feedback loop exacerbating the issue.

The problem here is that if you don't cover a large enough area, already have maxed suspension and/or don't tie the different parts of the house together enough, the same energy is still going into your house and will still find some way to be dissipated. If it shook your house before, it will probably do so now. What you need is a way to dissipate it or reduce the energy being transmitted.

For noise you are doing exactly what you don't want. A slightly loose floor will absorb some of the noise (convert it to heat) and transmit the rest around the house. As we strengthen the floor it is unlikely that you will make it strong or massive enough such that that it stops noise from traveling through the material, and in fact most upgrades make the transmission MORE efficient as less sound is turned to heat and your walls effectively become speakers.

This method also ignores the walls, gaps, door and other areas for noise to escape and travel through your house.

2: The noodle

Put a foam noodle between the unit and the wall. You are damping the vibration of the unit. Works great... but...

If you put it in too tight or use too dense of a noodle/foam piece you are increasing the efficiency of the unit to transmit audio energy into your house and just spreading out the points absorbing the vibration, not reducing the energy reaching your walls.

A good rule is that you should be able to shove it in without pulling the unit out. Effect is somewhat limited, but it does help vibration. Unfortunately it does nothing for noise.

3: Rubber... This is the one that is probably good for everything if done right. The rubber pieces sold for washers act as a multiple durometer shock absorber. You don't want something too soft because that can help create a sympathetic vibration, but too hard just results in sound transmission yet once again.

The commercial absorbers are a good mix of hardness. Basically 4 multi-layer pieces of rubber under the feet. Great idea IMO. they really help to convert kinetic/sound energy generates into heat. You want that to happen.

Rubber sheets are also good, if done right. In practice the sheets are not installed tightly bound do the floor or each other so they are not as efficient as they should be. They are also generally not hard enough (at least in what is generally commercially available to a homeowner) and should be done in multiple varying hardness sheets to maximize effect. IF you do want to go this route you need to think thick, 1.5" or so and use glue between the floor and the sheet and between each sheet to make sure they act as a single unit to build up the mass of the floor. Otherwise get the commercial rubber vibration reducers from lows or hd.

So what to do?

First, keep in mind that audio sound proofing is extremely complex. ANY gaps will let the air sound (pressure levels) escape. If you have a vent based unit, you can't completely close off the room. You could go to a solid door on the laundry room, but can't install weatherstripping. If you have gas... talk to your local government people to understand code. LOTS of issues you have to take into account because gas requires o2

If I had to go about it I would use a solid door and install a vent from laundry room to house that has a bend with an insulated flexible pipe so as to force the sound to take a turn and to not make it easy to move. Local code rules here though, don't do anything without discussing with an expert!

If it is ventless/condensing and electric, go for making it a self contained room. Use an exterior door weatherstripping system and upgrade to a solid door so you aren't allowing air/sound to move in and out. This will make a HUGE difference for noise right off the bat.

Second thing to look at is back to vibration reduction. Make sure the shipping bolts are out. I've read HUNDREDS of accounts of this so far and makes me sad that the installers are so bad, but it isn't surprising.

Then get to leveling. Yes, before you ask even moving the unit an inch or two matters and requires re-leveling (incuding looking behind the unit to find that one sock that went back there). Floors are not even in the least and can even change over time.

Warning: Don't use the wrong tool for the job. A 6" level is for a small picture frame. Use a 4' level to get a highly accurate picture (hah). It will hang off the edge of the machine, but it will be the best way to go about leveling. If you can't due to space restrictions, get something that matches the size of the washer but again a 6" or even 12" is not accurate enough. Make sure the bubble is EXACTLY in the center of the lines, not "somewhere" in between. Thats 1-2 mm at the edge which is significant.

Give it a run and see how it spins. If done right, the vibration will be gone without anything in the washer. If you put something in and it starts vibrating the heck out of your house, then you have to consider that either the washer/dryer or flooring are the issue. Double check the bolts. If you STILL get vibration, put the rubber feet under the unit, re-level and try again.

Still getting vibration with stuff falling off the walls downstairs? Ok fine, looks like the floor isn't tight enough. Before fixing it, lets read on, I'll get back to that part.

Next upgrade is to look at how the sound is transmitted through the walls and floor. Sound is nothing but pressure waves in air. Solid objects can transmit these waves, and the more solid they are, the more efficient they can move (up to a point). In sound control rooms or other "soundproof" rooms the goal is to disconnect the path of the sound so it can't escape. This is done by sealing the room off (discussed above) and by putting some kind of membrane between the interior and exterior of the room.

For instance, you can build a room within a room. More stud walls that are non-structural that carry the drywall/plaster and use a rubberized membrane between the bottom and floor. Subflooring is put on a secondary joist system and not the joists that connect to the ceiling below. Anywhere you have a connection from this inside room to the outside you need to use greenglue or some other very heavy adhesive. Drywall can be attached with j or z channels. etc etc Search for sound proofing. Lots of huge books on it.

For the case of a laundry room I think we can safely say that the scope is going to be smaller than a fully soundproofed room, and in fact the two directions we are most concerned about are through the door and through the floor. Door is covered so what about floor?

First, make sure there are no air gaps. If you have them, they should be filled with caulk or some other filler.

Cover the floor with rubber.

If you want to step it up a notch, you could use a lead/rubber combo with greenglue (or the like) attaching it between layers and to the floor . This would massively (hah, get it?) increase the mass of the floor (not stiffness), hopefully limiting vibration passage as well as turning more sound into heat.

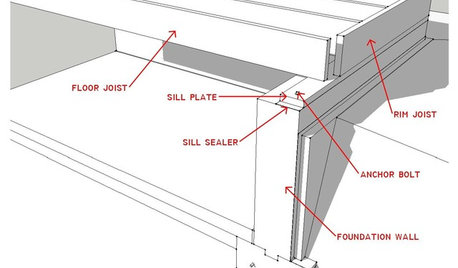

Even better is to disconnect the floor from the joists below. This gets into difficult or expensive work, but it is the best way to do it. You would need to pull up the subfloor boards and somehow make the floor "float" above the joists. Easiest way is to put greenglue or a sound absorbing high density foam onto of the joists, then re-attach the floor so it doesn't direct touch the joists at all and the membrane is in-between. Then put the rubber mat on top of that, then cover with whatever floor covering you want that would be happy on the rubber.

If you wanted to go hog wild you would build a secondary frame with more greenglue or other soundproofing material between the frame and joists and use that to attach new heavy duty subflooring to that.

If you go this route then you do want to put bracing in the joists to increase its strength. Check to make sure it is tied in to other areas of the house properly to increase the mass/strength. Use irregularly spaced braces as well to damp sound even more.

My one caution for useless procedures that might seem to make sense. Don't add insulation. At least not the stuff you are thinking about as it is just too light. You would need VERY massive stuff to make a difference and then it still needs to leave air gaps as air is better at stopping sound than solid objects at transmission uh it gets complex. If you want to go this route read some books on sound proofing.

Finally you should have an absolutely silent laundry room.

If you are wondering, I have a solid door, no weatherstripping and the commercial rubber vibe blocks in mine. My house is nice and strong, but I am sure it could be stronger. That being said it is good enough.

I could do more but the gain is not really worth the cost and between the block and the leveling (leveling did the most) my front loader running at 1300rpm is absolutely fine. Even when loaded bursting full of bedding or towels.

oregpsnow

kjmama

Related Discussions

Lawn-Boy Duraforce Rejetting...one experience

Q

help-I have an overwhelming deck mess

Q

2nd floor laundry room do's and don'ts

Q

Sink primer?

Q

Tosca Necoechea