Cracked Floor Joist

ohmmm_gw

9 years ago

Featured Answer

Sort by:Oldest

Comments (40)

bus_driver

9 years agolast modified: 9 years agoJoseph Corlett, LLC

9 years agolast modified: 9 years agoRelated Discussions

Inspection $19,000 estimated for repairs - foundation question

Comments (5)If there is a structural concern, you can hire a structural engineer. A general home inspector will not know as much as they do, and may over or under call the severity of the problem. As far as not having zoned heat, that is quite common and I do not believe it is reasonable to ask the seller to switch to zoned heat. It is nice if you are willing to accept bathrooms as is since you will be updating. You need to decide if any of the disclosed conditions are deal breakers for you if the seller refuses to give you a credit to repair them. Some of the brinck issues I am not sure if they need to be fixed now or if condition is simply being noted. I would much prefer a credit since the seller would likely fix in the cheapest possible way. If the water heater is safety issue I would fix before moving in. No house is perfect. On our house there were clerestory windows with broken seals and humidity within the panes. The seller did agree to credit us up to our pre agreed repair cost. It bothered me at first, but we never fixed it and I never even notice it anymore. $19,000 is a lot in repairs. But since I am not clear what is absolutely needed vs rec to get the house as perfect as possible, i am not sure it would scare me away. And the amount I would be willing to pay for myself would depend on the market and how much I wanted the house. Windows and doors could be as simple as painted or need a little planing the inspector would not do. With my house, there were a number of thermostats they noted did not work, when the only problem was a dead battery inspectors were not willing to replace. The inspector noted loose toilets as well as a problem with a water heater and other plumbing issues. The plumber said the toilets were not loose and the water heater was also fine. (In other words, I trusted the licensed plumber I have used many years more than the general home inspector) Also, a contractor's estimate is an actual estimate vs the inspector's guesstimate. Best wishes, these are the types of things that can easily kill a sale. But, big problems can be worked through if you and the sellers can agree on a fair price adjustment. lafdr...See MoreFloor Joists, I-Joist or Dimensional 2x?

Comments (10)I can't think of an advantage in using 30 ft long floor framing members that only span 15 ft. but the obvious disadvantage would be the high cost. Many codes now require a drywall ceiling below I-Joists so a basement ceiling might be required. 11 7/8" I-Joists are considerably stronger than 2x10 dimension lumber so those are unlikely to be equivalent choices. The reason to use I-Joists is that they can span longer distances and 15 ft is not a span long enough to require using them. 2x10's would meet code and 2x12's would be stiffer and less bouncy....See MoreCracked Floor Joist at Knot in Basment

Comments (8)The finished floor above is all level. My concern is that the floor joist will continue to crack and get worse, this is my main concern. I am leaning towards jacking the cracked portion up so that it is in line, and then sistering two 2x7 boards, approximately 5 feet long, on each side with lag bolts. Would this provide adequate support? Is there concern with doing to much/overkill? Any thoughts would be much appreciated on this topic....See MoreBuying a home with cracked floor joists?

Comments (2)Never mind, got an answer on another forum....See Moreklem1

9 years agolast modified: 9 years agokudzu9

9 years agolast modified: 9 years agoJoseph Corlett, LLC

9 years agolast modified: 9 years agokudzu9

9 years agolast modified: 9 years agoohmmm_gw

9 years agolast modified: 9 years agoklem1

9 years agolast modified: 9 years agoJoseph Corlett, LLC

9 years agolast modified: 9 years agojdubb

9 years agolast modified: 9 years agoklem1

9 years agolast modified: 9 years agobus_driver

9 years agolast modified: 9 years agosombreuil_mongrel

9 years agolast modified: 9 years agoJoseph Corlett, LLC

9 years agolast modified: 9 years agoJoseph Corlett, LLC

9 years agolast modified: 9 years agokudzu9

9 years agolast modified: 9 years agobus_driver

9 years agolast modified: 9 years agotalley_sue_nyc

9 years agolast modified: 9 years agokudzu9

9 years agolast modified: 9 years agobus_driver

9 years agolast modified: 9 years agoklem1

9 years agolast modified: 9 years agoJoseph Corlett, LLC

9 years agolast modified: 9 years agobus_driver

9 years agolast modified: 9 years agogrubby_AZ Tucson Z9

9 years agolast modified: 9 years agokudzu9

9 years agolast modified: 9 years agobus_driver

9 years agolast modified: 9 years agokudzu9

9 years agolast modified: 9 years agoklem1

9 years agolast modified: 9 years agotalley_sue_nyc

9 years agolast modified: 9 years agoklem1

9 years agolast modified: 9 years agokudzu9

9 years agolast modified: 9 years agotalley_sue_nyc

9 years agolast modified: 9 years agokudzu9

9 years agolast modified: 9 years agoohmmm_gw

9 years agolast modified: 9 years agokudzu9

9 years agolast modified: 9 years agoJoseph Corlett, LLC

9 years agolast modified: 9 years agoohmmm_gw

9 years agolast modified: 9 years agoJoseph Corlett, LLC

9 years agolast modified: 9 years agoJohn Teets

6 years ago

Related Stories

DESIGN DICTIONARYOpen Web Steel Joist

Give your roof or floor a support network, woven between the beams

Full Story0

BATHROOM TILEQuick Fix: Repair Cracked Bathroom Grout

Banish an eyesore and safeguard your bathroom from water damage in 30 minutes or less with this DIY repair

Full Story

CONCRETEWhy Concrete Wants to Crack

We look at the reasons concrete has a tendency to crack — and what you can do to help control it

Full Story

PATIOSPatio Details: Good-bye Cracked Concrete, Hello Lush Garden

A San Francisco couple replace an old parking space with a barefoot-friendly outdoor retreat for eating, entertaining and play

Full Story

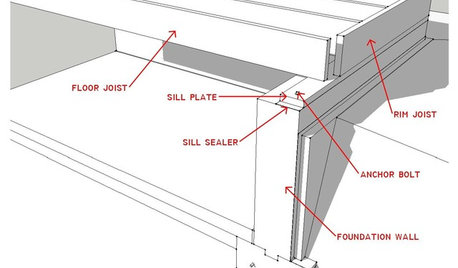

KNOW YOUR HOUSEKnow Your House: What Makes Up a Floor Structure

Avoid cracks, squeaks and defects in your home's flooring by understanding the components — diagrams included

Full Story

TILEWhy Bathroom Floors Need to Move

Want to prevent popped-up tiles and unsightly cracks? Get a grip on the principles of expansion and contraction

Full Story

GREEN DECORATINGGo Cuckoo for Coconut Furniture and Surfaces

Crack open a lesser-known ecofriendly design option: tiles, flooring, tables and more made from coconut shell and palm wood

Full Story

REMODELING GUIDESTransition Time: How to Connect Tile and Hardwood Floors

Plan ahead to prevent unsightly or unsafe transitions between floor surfaces. Here's what you need to know

Full Story

WOODTry DIY Plywood Flooring for High Gloss, Low Cost

Yup, you heard right. Laid down and shined up, plywood can run with the big flooring boys at an affordable price

Full Story

bus_driver