craftsman wont move

ncgrass

14 years ago

Related Stories

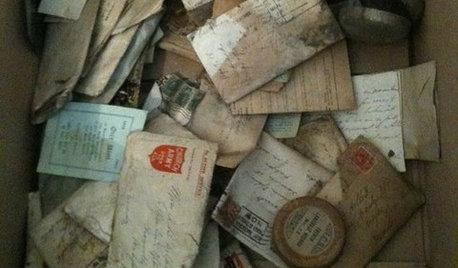

REMODELING GUIDESYou Won't Believe What These Homeowners Found in Their Walls

From the banal to the downright bizarre, these uncovered artifacts may get you wondering what may be hidden in your own home

Full Story

SMALL SPACESHouzz TV: You Won’t Believe Everything This Tiny Loft Can Do

Looking for more floor space, a San Francisco couple hires architects to design a unit that includes beds, storage and workspace

Full Story

SMALL SPACES10 Tiny Kitchens Whose Usefulness You Won't Believe

Ingenious solutions from simple tricks to high design make this roundup of small kitchens an inspiring sight to see

Full Story

HOME TECH3 Kitchen Contraptions You Won’t Believe

Pizza hot from the printer, anyone? These cooking gadgets harness imagination and high tech — and have price tags to match

Full Story

FURNITURE12 Sofa Colors That Won't Box You In

With any of these colors as a base, you can change your decor as often as you change your mind

Full Story

LIFEYou Said It: ‘Put It Back’ If It Won’t Help Your House, and More Wisdom

Highlights from the week include stopping clutter from getting past the door, fall planting ideas and a grandfather’s gift of love

Full Story

PATIOSPatio Details: Dog Won’t Trample the Plants With This Design

An Asian-inspired backyard redo adds clean lines, a new water feature and a sense of spaciousness — with room for a large beloved dog

Full Story

BUDGET DECORATING15 Summery Decorating Ideas That Won't Break the Bank

Transport yourself seaside with a bit of paint or a few airy accessories

Full Story

KIDS’ SPACES7 Kids’ Bedroom Decor Ideas That Won’t Break the Bank

Take an economical approach to decorating your child’s room with these DIY ideas

Full StorySponsored

More Discussions

tomplum

mownie

Related Discussions

Craftsman Kohler 20hp mower won't start

Q

Craftsman Riding Mower blades won't engage

Q

Craftsman 20HP Mower won't start

Q

Craftsman riding mower won't turn over

Q

rcmoser

ncgrassOriginal Author

tomplum

rustyj14

ncgrassOriginal Author

mownie

ncgrassOriginal Author

mownie

ncgrassOriginal Author

mownie

tomplum

rustyj14

trobinett

mownie

rcmoser

ncgrassOriginal Author

rustyj14

mownie

ncgrassOriginal Author

mownie

ncgrassOriginal Author

mownie

ncgrassOriginal Author

mownie

montanastang

mownie

montanastang

montanastang

mownie

montanastang

tomplum