Greenhouse film on stoophouse in summer?

tentman

15 years ago

Related Stories

OUTBUILDINGSStudio Solution: A Kit Greenhouse Becomes a Creative Private Office

See how an inventive work-from-home designer made an office from a greenhouse, for some inspired thinking in the backyard

Full Story

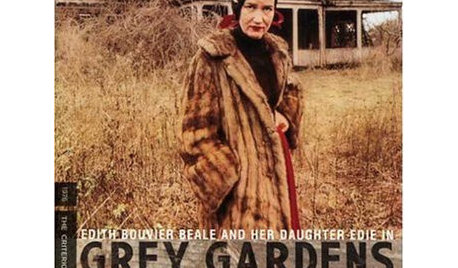

FUN HOUZZ10 Leading-Role Movie Houses

Architecture and interior design steal the show in these 10 house-focused flicks

Full Story

TRADITIONAL HOMESMy Houzz: A Centuries-Old French Estate Charms Again

Time and local artisans help a couple realize an idyllic French country retreat — and you can rent it

Full Story

MATERIALSMaterials Workshop: Polycarbonate — a Low-Cost Alternative to Glass

Looking for something lighter, stronger and less expensive than glass? Multiwall polycarbonate may be a good option

Full Story

HOUZZ TOURSHouzz Tour: A Contemporary Retreat on a British Moor

Once nearly uninhabitable, this 18th-century farmhouse is now a beautiful example of ecofriendliness and self-sufficiency

Full Story

GREAT HOME PROJECTSHow to Add a Skylight or Light Tube

New project for a new year: Increase daylight and maybe even your home’s energy efficiency by opening a room to the sky

Full Story

FARM YOUR YARD14 Crazy Places to Grow Edibles

Some Houzzers may lack ground for gardening, but they’re never short on imagination

Full Story

GREAT HOME PROJECTSHow to Install Energy-Efficient Windows

Learn what Energy Star ratings mean, what special license your contractor should have, whether permits are required and more

Full Story

FUN HOUZZHouzz Call: Tell Us About Your Dream House

Let your home fantasy loose — the sky's the limit, and we want to hear all about it

Full Story

KITCHEN DESIGNThe Return of the High-Back Farmhouse Sink

See why this charming and practical sink style is at home in the kitchen and beyond

Full Story

ekgrows

bcfromfl

Related Discussions

Greenhouse temperature control: big problem

Q

evolving simple hoop greenhouse

Q

removing greenhouse plastic for the summer

Q

Double film blower question

Q

tentmanOriginal Author

tentmanOriginal Author

crabbcat

bcfromfl

tentmanOriginal Author

bcfromfl

tentmanOriginal Author

tentmanOriginal Author

bcfromfl