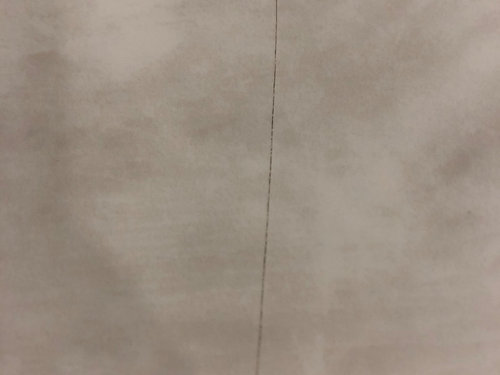

New Porcelain Countertop Hairline Fracture :(

3 years ago

last modified: 3 years ago

Featured Answer

Sort by:Oldest

Comments (67)

Related Discussions

Hairline crack in porcelain bathroom sink

Comments (4)OP, Before you replace just the sink, consider the cost of replacing the entire unit. I have a very similar vanity/ top / sink that came from Lowe's and was not terribly expensive ($350). The one that you have isn't in bad shape, but if you wanted to change styles, or if it was otherwise damaged this would be an opportunity to swap it out. BTW: The bowl is probably sealed to the granite with silicone sealant - you will have to cut it from the top after removing the bolts. You don't use plumbers putty on granite. Also, the top is pretty much permanently attached to the base. I was going to take the top off mine when I brought it home to make the installation easier and lighter... I think it was epoxied on to the sink base. I do agree, however, that the sink is probably fine. If the crack gets bigger or leaks, deal with it then. Here is a link that might be useful: Sink and base This post was edited by jakethewonderdog on Wed, Sep 3, 14 at 9:02...See MorePorcelain kitchen countertop

Comments (19)Onlybaba yes I did carry out my appointment to see and discuss the Neolith. I came in a day after the Neolith rep was there...lucky me! They said the rep did a demonstration on the silk finish Neolith Calacutta sample I had taken home and returned (I took pics of samples while at home below). The demo was taking a screw driver and smashing it over and over on the surface of the Neolith and it didn't leave a mark! I was impressed and asked if they sold a lot of it? They said they literally just got the Neolith display 2 weeks prior to me coming in! I did not know that. Cp I did ask the owners wife again about the frying pan thing and she laughed and said after seeing the demo she feels differently and not to let the beauty skew one of its durability. I still absolutely love it, but am leaning against it for a couple of reasons. First I was going to do a small island and thought the pattern did not fit the scale of the island size. Then I changed to a larger island but then thought the use of it on the island and around the perimeter was overkill as I need about 85 sq ft. Also, decided I would rather keep with the same material for whole kitchen as I'm not big on mixing too many different materials and liked the idea of less waste using one material too. The other reason was the quote I received for the Neolith vs DuPont Zodiaq London Sky was almost double. :o yikes! and again for the amount of square footage needed...ah no! I'm not ruling it out the Neolith for use in our master bath and half bath. But for now I'm really leaning towards Quartz Masters Organic White. It's a quieter, softer look and resembles more of a Carrara marble as opposed to a Calacutta. Hope this helps! :) Here are some pics below: (side shot so you can see the finish) Neolith calacutta silk (top) Neolith calacutta polished (middle) Quartz Masters Organic White (bottom) I would describe the silk finish look like honed, the polished look like high gloss, and the Quartz look between the two actually it looks like when I get hairspray on my porcelain guest bath counter. Keep us posted if you get any more info and what you decide. pipdog gorgeous! and my comment about scale of pattern to size of island stands true as I see how well it works and looks on your big island...awesome choice! And beautiful view btw!...See MoreI have chips on my new cambria countertops

Comments (76)@Joseph Cornett, LLC I posted on another thread and sent you a message. Our Cambria countertops arrived with the wrong profile (it came with sharper edge Ridgeline and we ordered quarter round Summit to help with chips). The installer is removing it today, Cambria is picking it up tomorrow and taking it back to their location to fix. Cambria does the cutting in our area, probably because we are close~ about 3 hours. I was told by our installer that the sink would stay the same "sharper" edge, specifically ZR. I then confirmed in a phone call to Cambria that they "typically" do one standard edge profile on undermount sinks. Is this right? I am at my wit's end with this whole house construction. It has been non-stop problems and mistakes....See MoreCracks around sink on new calacatta quartzite countertops

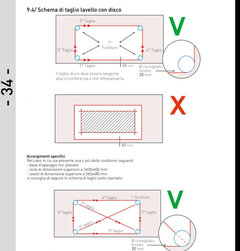

Comments (19)@tracsurf What I've heard just from my own general research is that you need a lot of water for cutting these delicate stones. I've been told that "everyone" will be using water with a saw to cut natural stone, but you need someone who uses a lot of water. I've seen one fabrication shop that even had drain valleys cut all throughout the floor of the shop to manage the water overflow. If you can find anyone who successfully fabricates and installs Neolith or porcelain slabs without cracks on a regular basis, they'll be equipped with better supplies and processes to also fabricate quartzite without cracks., though some quartzite is definitely more problematic than others. You can ask around at all the slab yards near you if any fabricator is known for being well-equipped for quartzite fabrication and experienced. I found two in my area this way, Escobar Marble and Active Granite, both in Dallas, Texas. If they aren't in your area, you might give Active Granite (the larger shop) a call and quiz them on what types of equipment they have to get leads for someone similar in your area. Both these places came highly recommended to me as shops that had the proper equipment to fabricate, transport and install delicate materials in comparison with other shops that simply didn't have the right equipment and tools for preventing cracking....See More- 3 years ago

- 3 years agolast modified: 3 years ago

- 3 years agolast modified: 3 years ago

- 3 years agolast modified: 3 years ago

- 3 years ago

- 3 years ago

- 3 years ago

- 3 years ago

- 3 years ago

- 3 years agolast modified: 3 years ago

- 3 years ago

- 3 years ago

- 3 years agolast modified: 3 years ago

- 3 years ago

- 3 years ago

- 3 years ago

- 3 years agolast modified: 3 years ago

- 3 years ago

- 3 years ago

- 2 years agolast modified: 2 years ago

- 2 years ago

- 2 years ago

- 2 years ago

- 2 years ago

- 2 years agolast modified: 2 years ago

- 2 years ago

- 2 years agolast modified: 2 years ago

- 2 years ago

- last year

- 7 months agolast modified: 7 months ago

- 7 months ago

- 7 months ago

- 7 months ago

- 7 months ago

- 7 months agolast modified: 7 months ago

- 7 months ago

- 7 months agolast modified: 7 months ago

- 7 months agolast modified: 7 months ago

- 7 months agolast modified: 7 months ago

Related Stories

KITCHEN DESIGNHouzz Quiz: What Kitchen Countertop Is Right For You?

The options for kitchen countertops can seem endless. Take our quiz to help you narrow down your selection

Full Story

MOST POPULARYour Guide to 15 Popular Kitchen Countertop Materials

Get details and costs on top counter materials to help you narrow down the choices for your kitchen

Full Story

KITCHEN COUNTERTOPSWhat’s the Difference Between Quartzite and Quartz Countertops?

Weigh the pros and cons of these popular kitchen countertop materials

Full Story

OUTDOOR KITCHENSYour Guide to the Top Outdoor Kitchen Countertop Materials

Houzz pros share the best options for different climates, budgets and styles — and one to avoid

Full Story

MATERIALSNew Looks for Engineered Countertops and Other Surfaces

See the top colors and styles for new engineered surfaces introduced at the 2021 KBIS trade show

Full Story

KITCHEN COUNTERTOPSDesigners Dish on Their Top Materials for Kitchen Countertops

Find out which countertop materials and styles these pros are favoring in their kitchen designs

Full Story

KITCHEN COUNTERTOPS7 Low-Maintenance Countertops for Your Dream Kitchen

Fingerprints, stains, resealing requirements ... who needs ’em? These countertop materials look great with little effort

Full Story

KITCHEN DESIGNNew Looks for Cabinets and Countertops Emerging in 2019

Dark colors, wood patterns and thin surfaces are a few of the trends seen at the recent Kitchen & Bath Industry Show

Full Story

KITCHEN DESIGNThe Future of Backsplashes

Grout is out. Continuous sheets of glass, stone, metal and porcelain are saving cleaning time and offering more looks than ever

Full Story

KITCHEN COUNTERTOPSKitchen Counters: Concrete, the Nearly Indestructible Option

Infinitely customizable and with an amazingly long life span, concrete countertops are an excellent option for any kitchen

Full Story

Louise Smith