Latest Insulation Technique - Interior Basement Walls

whaas_5a

5 years ago

last modified: 5 years ago

Featured Answer

Sort by:Oldest

Comments (6)

Related Discussions

Basement with Existing Stud Walls - Insulation Options

Comments (4)1.5-2" is the 'norm' in climates similar to mine, but not sure if there's a definitive resource on this. That's on the wall. But the total R Value should be higher. And that can be achieved with lower cost fibrous insulation or EPS (expanded polystyrene) added between the studs. Another alternative--in cold or mixed climates only--is the use of a MemBrain "smart" vapour retarder with fiber insulation. Of course, any system composed in part of moisture sensitive materials is at risk from groundwater....See MoreTo insulate or not to insulate a basement bathroom??

Comments (9)worthy -- thanks for replying... unfortunately, I can not slide in the XPS behind the studs. By local code, we had to install fire blocking on the end of the wall. So now it is closed off. And, I can't install XPS in between the studs becuase I already have electrical and piping running through the studs. The gap between the wall and the stud is only a little more than 1/2". So even if I could slide in the XPS behind the studs, I would only get about r 3 value.... Thats why I figured it is almost better to put no insulation. The pipes arent gonna freeze; Plus, if I do get moisture back there, then there will be no fiberglass insulation to get wet. With no insulation, the wall will just dry out. (with the help of my dehumidifers and the bathroom vent fan, of course) If I get a chance, I will post a picture tonight of the studded wall with the roughed-in plumbing and electrical. thanks again. mm I'll try to post a picture later.......See MoreTo insulate or not to insulate a basement bathroom??

Comments (2)I've often written about foam being better than batts. In a concrete basement below grade there will be no air pressure differential to cause air movement from the outside in. Batts are OK here. The bathroom is not going to be sealed from the rest of the house, so whether the batts are faced or not is not a big deal. That is my view. Others may be more precise about reasons for one or the other. Definitely do insulate. It's a more comfortable room afterwards. The temperature gradient is lessened. Batts are OK. Any kind of batt. If you want to do somthing better, you could use spray foam but that is a whole new learning curve. Batts are easy. Methinks a little knowledge can be a dangerous thing....See MoreBasement wall insulation

Comments (3)I'm presuming one material is offset by 2" from the other. In that case, attach the foam to both materials separately. And where they meet, use narrow strips on top of or underneath so that all surfaces are covered and sealed. If that's not the situation, post a photo....See Morewhaas_5a

5 years agolast modified: 5 years agoworthy

5 years ago

Related Stories

SELLING YOUR HOUSEHome Staging to Sell: The Latest Techniques That Really Work

Get up to speed on the best ways to appeal to potential buyers through accessories, furniture, colors and more

Full Story

MODERN HOMESHouzz Tour: 800-Year-Old Walls, Modern Interiors in Provence

Old architecture and new additions mix beautifully in a luxurious renovated vacation home

Full Story

BRICKHow to Make an Interior Brick Wall Work

Learn how to preserve, paint, clean and style a brick wall to fit your design scheme

Full Story

REMODELING GUIDES11 Reasons to Love Wall-to-Wall Carpeting Again

Is it time to kick the hard stuff? Your feet, wallet and downstairs neighbors may be nodding

Full Story

BASEMENTSBasement of the Week: Fun for All Ages in Connecticut

Crafts, wine, billiards and ... soccer? Yup, this tricked-out family basement has room for all that and more

Full Story

DOORSLet's Walk Through the Latest Door Trends

The functional feature has been getting a dose of flexibility, creativity and glamorous detail

Full Story

WALL TREATMENTSThese Are Not Your Grandfather’s Pine Walls

The knotty look went from popular to pariah in years past, but today’s designers are finding new and stylish ways to embrace it

Full Story

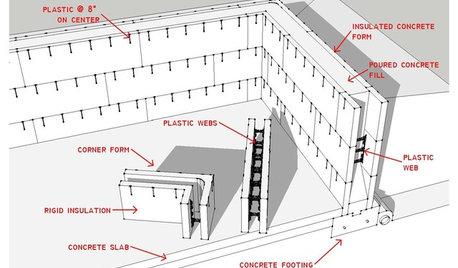

KNOW YOUR HOUSEKnow Your House: The Basics of Insulated Concrete Form Construction

Get peace and quiet inside and energy efficiency all around with this heavy-duty alternative to wood-frame construction

Full Story

TRADITIONAL HOMESHouzz Tour: Basement Now a Light-Filled Family Living Space

Merging a house and a basement flat into one townhouse creates a spacious family home in London

Full Story

GREEN BUILDINGInsulation Basics: Heat, R-Value and the Building Envelope

Learn how heat moves through a home and the materials that can stop it, to make sure your insulation is as effective as you think

Full Story

worthy