Floor Joists: Lumber, I-Joists or Trusses

Pinebaron

7 years ago

last modified: 7 years ago

Featured Answer

Sort by:Oldest

Comments (37)

Pinebaron

7 years agoRelated Discussions

Rim Joist and floor joists rot (pic heavy).

Comments (6)I would be concerned how much the floor is out of level and if that has compromised the operation of any doors. You might need to take the load off of the framing in order to repair/replace the damaged portions. It is wise to use Grace water based primer (WB Primer) behind any Vycor adhered directly to sheathing (especially OSB) if you don't want water to get behind it. Unfortunately, it is usually sold in 5 gallon containers. Tyvek HomeWrap is pretty watertight (unlike most other housewraps) but it is not very abrasion resistant so I would not use it or any vinyl product as flashing. Avoid the use of unfinished aluminum sheet flashing against pressure treated wood or anywhere else where it will be in constant contact with water....See Morewater stain at sill plate, rim joist, and floor joist

Comments (8)"For the stucco cracks, can I just use caulking to fix it" No, it will only slow down the penetration from the cracks. The damaged underlayment/flashings need to be repaired in order to keep the area's framing dry. Stucco, or hard coat in your case, isn't waterproof. It's the underlayment/flashings/drainage plane that keep the wall/floor cavaties dry. It doesn't take physical water,(rain, sprinklers, leaks, etc.), for your framing to get wet. It can be from condensation/ moisture build-up behind the cementious coats. That's why it's important to have what's behind the coats in good working order to keep moisture or physical water out. These days, most underlayments for traditional stucco are double plyed. With single ply underlayments, the scratch coat attached to the undelayment can cause moisture build-up behind. The two ply application is geared for the second ply to catch that moisture and allow it to run down and out the weep screed,( drainage plane). Your best bet is to have it repaired by a reputable, experienced outfit. Another avenue would be to get estimates on an elastomeric or acrylic top coat, but in order for that to tie in right, it would be a whole house application. Someting to consider if you were thinking of re-coating anyhow. Elastomeric top coats remain flexible in temperature changes meaning virtually crack free finishes, and is way more water resistant than traditional stucco or hard coats....See MoreFloor Joists, I-Joist or Dimensional 2x?

Comments (10)I can't think of an advantage in using 30 ft long floor framing members that only span 15 ft. but the obvious disadvantage would be the high cost. Many codes now require a drywall ceiling below I-Joists so a basement ceiling might be required. 11 7/8" I-Joists are considerably stronger than 2x10 dimension lumber so those are unlikely to be equivalent choices. The reason to use I-Joists is that they can span longer distances and 15 ft is not a span long enough to require using them. 2x10's would meet code and 2x12's would be stiffer and less bouncy....See More2x8 Joists are 1.75x7.75 and 2x6 Joists are 1.75x5.75? why is this?

Comments (4)Believe me, it could be a lot worse. In the mid 1960s, 2x4s measured 1 5/8 by 3 5/8 for a few years. Remodeling, especially after 2x4s became 1.5 by 3.5, often became a nightmare of shimming and head-scratching. To answer your question, lumber dimensions are smaller than stated for two reasons. One, it's just easier to use round numbers - 2x4, 2x6, 2x8, etc - than 1.5x3.5, 1.5x5.5, 1.5x7.25, etc (catch that? 2x4s and 2x6s shrunk in width by 1/2 inch, everything larger shrunk 3/4 inch, so 2x8s are 1.5x7.25, 2x10s are 1.5x9.25, 2x12s are 1.5x11.25). Two, lumber is now sized for performance. To put it another way, a 2x4 - actual two inch by four inch - is wasteful. 1.5x3.5 does just as good for the job intended....See MorePinebaron

7 years agolast modified: 7 years agoPinebaron

7 years agolast modified: 7 years agoPinebaron

7 years agolast modified: 7 years agoworthy

7 years agolast modified: 7 years agoBT

7 years agoPinebaron

7 years agomushcreek

7 years agoUser

7 years agoPinebaron

7 years agoUser

7 years agolast modified: 7 years agobry911

7 years agoPinebaron

7 years agolast modified: 7 years agoVirgil Carter Fine Art

7 years agoPinebaron

7 years agoVirgil Carter Fine Art

7 years agolast modified: 7 years agoPinebaron

7 years agoUser

7 years agolast modified: 7 years agoPinebaron

7 years agoVirgil Carter Fine Art

7 years agolast modified: 7 years agoPinebaron

7 years agolast modified: 7 years agoPinebaron

7 years agolast modified: 7 years agoworthy

7 years agolast modified: 7 years agoPinebaron

7 years agoAndy

7 years agolast modified: 7 years agoworthy

7 years agolast modified: 7 years agoPinebaron

7 years agoPinebaron

7 years agoRon Natalie

7 years agoPinebaron

7 years ago

Related Stories

DESIGN DICTIONARYOpen Web Steel Joist

Give your roof or floor a support network, woven between the beams

Full Story0

DECKSDecking Materials Beyond Basic Lumber

Learn about softwoods, tropical hardwoods, composites and more for decks, including pros, cons and costs

Full Story

REMODELING GUIDESSupporting Act: Exposed Wood Trusses in Design

What's under a pitched roof? Beautiful beams, triangular shapes and rhythm of form

Full Story

KITCHEN DESIGNWhat to Know About Using Reclaimed Wood in the Kitchen

One-of-a-kind lumber warms a room and adds age and interest

Full Story

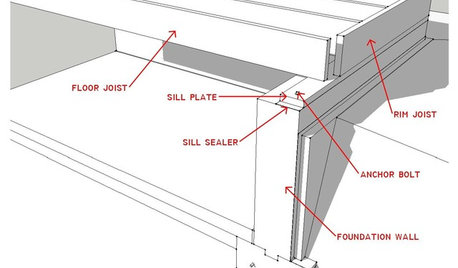

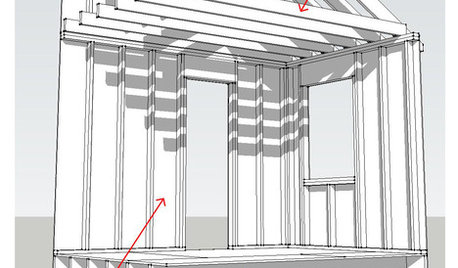

KNOW YOUR HOUSEKnow Your House: What Makes Up a Floor Structure

Avoid cracks, squeaks and defects in your home's flooring by understanding the components — diagrams included

Full Story

KNOW YOUR HOUSEKnow Your House: Components of a Roof

Don't get held up by confusion over trusses, rafters and purlins. Learn about a roof's features and their purposes here

Full Story

KITCHEN DESIGNSingle-Wall Galley Kitchens Catch the 'I'

I-shape kitchen layouts take a streamlined, flexible approach and can be easy on the wallet too

Full Story

REMODELING GUIDESDesign Dilemma: How Do I Modernize My Cedar Walls?

8 Ways to Give Wood Walls a More Contemporary Look

Full Story

DECORATING GUIDESFinish Your Floors to Perfection With Parquet

Add value and gorgeous detail to your home with timeless and elegant parquet flooring in a classic design

Full Story

Andy