Removing the flywheel holding bolt

websrchr1

9 years ago

Featured Answer

Sort by:Oldest

Comments (21)

websrchr1

9 years agoRelated Discussions

Removing Tecumseh rotary flywheel

Comments (13)Well I don't think I was getting ahead of myself because guess what, I didn't come off. This is really one of those things I wish I could be learning in person as that person would know how hard they could strike or not. I supported the flywheel (can see the endplay) and tried tapping and rotating. I used combinations of several smaller taps and a few more abrupt. I let penetrating oil sit for several hours. I reread all instructions and even maintained patience. Then the patience ran out and I knew damage would ensue. I know I'm missing something small, but I'm frustrated. After this is all done I will go back to my "parts" mower and try that to see if it is just this one that is particularly stuck. I may even go and try the Craftsman one last time to see if the penetrating oil did more with more time. The only reason I get to stop is because I decided to try removing the switch from below again and did manage to get it out. If the brake were not worn as far as it was I could not have done that. Now it's a matter of the "terminal" is always grounded and I can't figure out how it became like this or how to bend the wire so it disconnects properly. But I think I will likely just replace it also. So close yet so far. That balancer puller was shown in a list of accepted ways to do this. And cheap enough to win over fabbing one up quickly. But it comes back to one of my original issues, what do you do about the un-threaded holes in the flywheel. If someone would humor me in addressing that, do they have to be tapped with a traditional tap or were they just never meant to be used? I will probably never own or make the puller but unanswered questions tend to stick with me. Once this switch is fixed/replaced it will all be over and I will not likely have to work on a mower again for a while. You guys have been great, very helpful and supportive. I know more about my mower (and these engines in general) than I expected to learn in this period of time. Thanks....See Moreflywheel removeing from 14.5 briggs

Comments (3)The sheared flywheel key will not make a difference in removing the flywheel. B&S sells a simple, inexpensive puller that will safely pull your flywheel or you can make one yourself. Remove the crankshaft bolt. Remove the two studs on each side of the crankshaft holding the metal ring that secures the plastic cooling fan. Remove the plastic cooling fan, reinstall the crankshaft bolt without washer and run down to just above the flywheel. Drill holes in a pc. of flat stock, 3/8" thick or thicker by 1-1/4" to 1-1/2" wide to match the holes in the flywheel where the fan retaining ring studs were, drill oversize to make fit simpler. Buy two grade 8 bolts long enough to go thru the flat stock and 1/2" into the flywheel. Tighten them evenly, IF you get a lot of tension on them and the flywheel has not let go, hit the flat stock a good rap over the flywheel bolt. It may sound like you have broken things all to heck when flywheel lets go. Walt Conner...See Moreremoving flywheel from Stihl 2str motor

Comments (3)Stihl flywheels with provision is a cup molded around the retaining nut. This cup is threaded for a collar to thread in to. Then a push bolt is threaded in to the collar to push the flywheel off the crank. These flywheels tend to be stuck on harder then the others and should have the proper tools to remove them....See MoreCan't Remove Anchor Bolt on Toilet Bowl

Comments (30)Ok folks, I'm thrilled to announce that I was successful in removing the toy obstruction! I whipped out my angle grinder, removed the safety guard on it to get in tighter, and took it to the two bolts - they came off with ease. If I had to do it over, the only thing I would have done differently was to shimmy some cardboard pieces behind the grinder blade, just to protect the toilet bowl surface. You can see in the photo how the porcelain was marred slightly. I'm going to use Mr. Clean 'Magic Eraser's pad as a last attempts to clean up the black marks. But other than that, everything was smooth sailing. I dismounted the tank prior to lifting up the toilet, which help to reduce the load. Once I flipped over the toilet bowl, there was the toy stuck right at the end of the trap - it wasn't a pretty sight. It was jammed in there pretty good, so now I know why plunger, auger, and shop-vac failed. The install with the new wax ring went great and the toilet flushes very efficiently now. Incidentally, I also removed the seat cover from the toilet and couldn't believe how filthy those bolts were - again not pretty. So I'm ordering new seat covers for all the bathrooms in the house Thanks to everyone for sharing your thoughts and experience with me!...See Morerexlex

9 years agowebsrchr1

9 years agorexlex

9 years agoUser

9 years agolast modified: 8 years agotinkerer200

9 years agolast modified: 9 years agowebsrchr1

9 years agorexlex

9 years agolast modified: 9 years agotinkerer200

9 years agoUser

9 years agolast modified: 9 years agorexlex

9 years agotinkerer200

9 years agoUser

9 years agorexlex

9 years agoUser

9 years agorexlex

8 years agoUser

8 years agolast modified: 8 years agorexlex

8 years agoUser

8 years agorexlex

8 years ago

Related Stories

HOUSEKEEPINGIt’s Time to Clean Your Gutters — Here’s How

Follow these steps to care for your gutters so they can continue to protect your house

Full Story

LIFEReluctant DIYer’s Diary of a Dresser Makeover

Weekend project: Glossy new black-and-white dresser, hold the sandpaper

Full Story

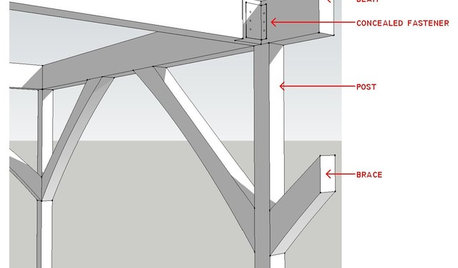

REMODELING GUIDESKnow Your House: Post and Beam Construction Basics

Learn about this simple, direct and elegant type of wood home construction that allows for generous personal expression

Full Story

DECORATING GUIDESCalifornia Law: License to Practice Interior Design?

A proposed bill that would require a license to practice interior design in California has Houzzers talking. Where do you stand?

Full Story

LIFEHow Your Landscaping Can Keep Burglars Away

Prevent home break-ins with strategic landscaping and good practices instead of menacing — and maybe less effective — measures

Full Story

LIGHTINGDecorating With Antiques: Set the Stage With Lighting

Complete a vintage scene or create contrast with lamps, sconces and chandeliers that have traveled through time

Full Story

DIY PROJECTSRefresh an Old Dresser With Leather Belt Handles

Give a tired piece of furniture a bright new look with loop handles made from a thrift store belt

Full Story

REMODELING GUIDESWhat to Know Before You Tear Down That Wall

Great Home Projects: Opening up a room? Learn who to hire, what it’ll cost and how long it will take

Full Story

ARCHITECTURELearn the Language of Trusses in Design

If figuring out all those intersecting beam configurations under roofs makes your eyes cross, here's help

Full Story

EXTERIORSSpecial Delivery: Keeping Your Packages Safe

Online sales are up, and so is the number of boxes delivered to homes. Here’s how to keep them beyond the grasp of porch pirates

Full StorySponsored

More Discussions

User