interesting TWP facts I just found

sweet11395

17 years ago

Related Stories

COLORBusted! Get the Facts for 8 Common Color Myths

Give hearsay the heave-ho — let these expert explanations improve your paint and decor choices instead

Full Story

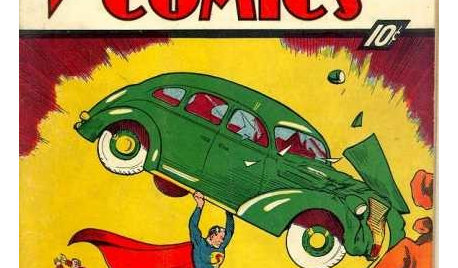

REMODELING GUIDESOne Guy Found a $175,000 Comic in His Wall. What Has Your Home Hidden?

Have you found a treasure, large or small, when remodeling your house? We want to see it!

Full Story

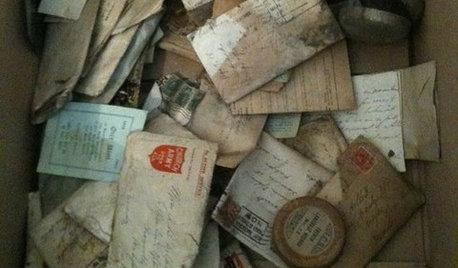

REMODELING GUIDESYou Won't Believe What These Homeowners Found in Their Walls

From the banal to the downright bizarre, these uncovered artifacts may get you wondering what may be hidden in your own home

Full Story

ARCHITECTUREThat's Interesting! 6 Designs That Defy Labels

Get inspired by the lines and textures of these homes, categorized only by the fact that they have no category

Full Story

LIGHTING12 Fun Light Fixtures Made From Found Objects

Trash became treasure in these one-of-a-kind lights. See if they inspire your own DIY pendant project

Full Story

ACCESSORIESFound Objects: The Most Natural Decor of All

They're beautiful, plentiful and best of all, free. See how to turn surprise finds into uniquely personal displays

Full Story

RUSTIC STYLEKitchen of the Week: Found Objects and Old Italian Farmhouse Charm

A homeowner and her cabinetmaker create a personal version of European-inspired comfort and simplicity

Full Story

COLORBlack and White and Found All Over: Zebra Print

Don't Forget, Zebra Pattern is Made With Neutrals — Add it Anywhere!

Full Story

FUN HOUZZGardening Happiness Found ... in Potholes

Imperfections in roads and sidewalks become miniature works of art — and unlikely sources of joy — at the hands of a London gardener

Full Story

pressurepros

sweet11395Original Author

Related Discussions

I'm a chart geek - so I found this interesting

Q

Just sharing an article I found interesting

Q

Interesting fact about your parents?

Q

Meilland: The most interesting Rose fact I have read in months

Q

john_hyatt

gorillabuilder

pressurepros

sweet11395Original Author

pressurepros