I am planning on buying a water softener and related items and would like to get feedback on my plans:

Water Stats:

City water

9 gpg hardness

No iron or magnesium

1.03 ppm total chorine

Service flow rate= 5.2 gal/min (measured by bucket filled at outside faucet)

Peak demand flow rate is about 8 gal/min.

Water pressure= 40 psi

Actual water usage = 120 gal/day (measured by water company billing), but with the addition of a softener and RO filter, call it 150 gal/day to be generous. 3 people are in the house, no plans for more people.

1.5 baths

No shower jets, multihead showers, pool, artificial snow machines, etc.,

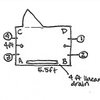

Because chlorine degrades the water softener resin, and also to capture chemicals, I plan to install a whole house backwashing carbon filter ahead of the softener. And I plan to install a Culligan Big Blue filter ahead of the carbon filter to grab grit.

Set for a weekly recharge, a water softener would remove (9 grains/gal) x (150 gal/day) x (7 days/week) = 9450 grains/week, making a 15000 size softener best for our needs.

I can set the softener at 6 pounds of dosing to remove 10000 grains of hardness.

What I think I want:

Softener:

15000 grain softener, mineral tank sized 7" X 44"

0.5 cu ft resin, 10% cross-link, standard mesh size

Fleck 5600SXT (electronic programable) valve

Transformer for Fleck 5600SXT

Upper distributor basket, standard size

Gravel underbedding

3/4 Inch Noryl Yoke with Noryl Bypass Valve

1 inch diameter riser tube

Standard mesh riser basket

Tubing to connect the control valve to the drain

(NO to: Res-Up, CanPro, Autotrol Turbulator, Vortech)

Brine tank:

Square 11x11x38 Brine Tank 156 lb capacity

4 inch brine well

Fleck 2310 Safety valve assembly

Brine tank cover

Brine overflow elbow

Hose for overflow

Salt grid

Tubing to connect the control valve with the brine tank

Whole house carbon filter:

10x44 resin tank

1 cubic foot of Centaur carbon

Gravel underbed

Fleck 5600SXT Auto Backwash Valve

Transformer for Fleck valve

3/4 Inch Noryl Yoke with Noryl Bypass Valve

Riser tube

Upper basket

Lower basket

Tubing to connect the control valve to the drain

Ahead of the carbon filter, I plan to install a Culligan Big Blue, 10", accessorized with a mounting bracket, special housing wrench, and food-grade silicone grease. I'll start with a 20 or 50 micron filter. If the Big Blue reduces pressure too much, I'll add a second one in parallel.

3/4" pipes and connections throughout.

I'll also install a RO system (Whirlpool WhER25), after the softener but that's fairly straightforward.

I finally decided against Vortech informed by AliceinWonderland's feedback and reasoning on a different thread. I realized that gravel is tougher than plastic.

What I'm undecided about:

1) The 10% crosslink resin is more expensive per bag than the supposedly superior Purolite SST 60. I don’t have an iron problem, but is there any reason to avoid the SST 60?

2) Whether or not to install pressure gauges at various points (between Big Blue filter and carbon filter, between carbon filter and softener, after softener).

3) Whether or not to install a hose bib for testing the water between the carbon filter and the softener. Do any forum participants have one installed and use it?

4) Getting a booster pump to compensate for water pressure loss. I will decide on this after everything is installed and we use it for a bit. Starting at 40 psi, with the sequence of Big Blue(s), whole house carbon filter, water softener, and then a split to a RO filter, I might end up with the water pressure of a damp sponge on a cold day. We'll see.

5) Using a larger brine tank (round 18x33, 240 lb capacity) instead of the 156 lb capacity I listed above. I'm expecting to use about 6 lbs of salt per week (see side notes below), so I think the smaller one would be OK. I can accept adding salt more frequently to the smaller tank with a benefit of having more free floor space.

6) Skip the Noryl bypass valves and install my own three valve bypasses with full port, 1/4 turn ball shut offs.

7) Getting a smaller 9" tank for the whole house carbon filter instead of a 10". The website listed a 10x44 tank for 1 cu ft of carbon, but it listed a 9x44 tank for 1 cu ft of softening resin. Does the carbon need that much more extra space than cation resin for some reason?

What I'd love feedback on:

A) Anything undecided above.

B) Is this plan reasonable?

C) Is the 15000 grain softener size correct?

D) Am I missing/forgetting/overlooking anything?

E) Anyone know a good source for pressure gauges so I can price them out? Or what I should be looking for/avoiding in a pressure gauge? I'm looking for something midrange.

Thanks for any feedback and comments!

User

SlugTheGardnerOriginal Author

Related Discussions

Watering houseplants with softened water

Q

Water Softener Sizing and grey water recycling of regen cycle

Q

plumber water softener on hot water side only????

Q

Water Softener not softening

Q

User