cub cadet lt1042 won't start

gardningscomplicated

13 years ago

Related Stories

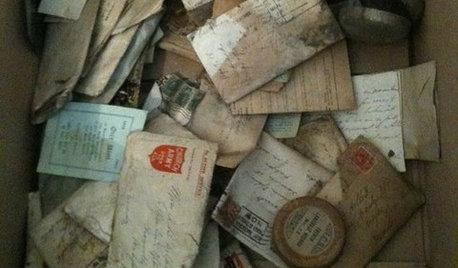

REMODELING GUIDESYou Won't Believe What These Homeowners Found in Their Walls

From the banal to the downright bizarre, these uncovered artifacts may get you wondering what may be hidden in your own home

Full Story

MOST POPULARHow to Start a Cool-Season Vegetable Garden

Late summer and late winter are good times to plan and plant cool-season crops like salad greens, spinach, beets, carrots and peas

Full Story

HOUZZ TOURSMy Houzz: A Family Makes a Fresh Start in a Remodeled Beach House

With neutral hues and ocean views, this Malibu home offers a stunning backdrop for gatherings of family and friends

Full Story

MORE ROOMS14 Bedrooms That Grow With Kids

You won't have to start from scratch every three years with these modern and eclectic kid's bedroom designs

Full Story

MOST POPULAROrganizing? Don’t Forget the Essential First Step

Simplify the process of getting your home in order by taking it one step at a time. Here’s how to get on the right path

Full Story

LIFEHard Winter? 9 Ways to Battle Cabin Fever

We know a lot of you are trapped where it just won’t stop snowing. Here are some ways to survive

Full Story

BATHROOM COLOR6 Bathroom Color Schemes That Will Never Look Dated

If you’d love to splash some color around your bathroom but fear it won’t stand the test of time, stick with these fail-safe combos

Full Story

MOST POPULARMy Houzz: Hip Midcentury Style for a Mom's Backyard Cottage

This 1-bedroom suite has everything a Texas mother and grandmother needs — including the best wake-up system money can't buy

Full Story

KITCHEN DESIGN8 Top Tile Types for Your Kitchen Backsplash

Backsplash designs don't have to be set in stone; glass, mirror and mosaic tiles can create kitchen beauty in a range of styles

Full Story

HEALTHY HOMEWhat to Know About Controlling Dust During Remodeling

You can't eliminate dust during construction, but there are ways to contain and remove as much of it as possible

Full StoryMore Discussions

mownie

gardningscomplicatedOriginal Author

Related Discussions

cub cadet LT1042

Q

Cub Cadet LT1042 Runs bad

Q

Transmission BElt Change on CubCadet lt1042

Q

won't cut in forward lt1042 cub cadet

Q

mownie

gardningscomplicatedOriginal Author

mownie

gardningscomplicatedOriginal Author

gardningscomplicatedOriginal Author

mownie

gardningscomplicatedOriginal Author

mownie

gardningscomplicatedOriginal Author

George Lawrence

rexlex

harry wookiee