Kubota GR2000/2100 Owners

jswan101

16 years ago

Related Stories

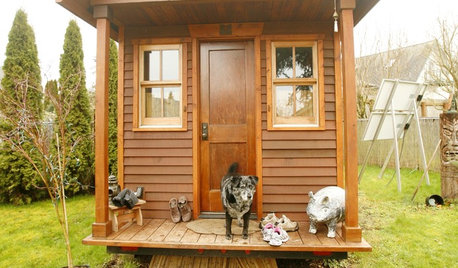

SMALL HOMESHouzz Tour: Sustainable, Comfy Living in 196 Square Feet

Solar panels, ship-inspired features and minimal possessions make this tiny Washington home kind to the earth and cozy for the owners

Full Story

TRADITIONAL ARCHITECTURE7 Classic Colonials Revamped for Today

See how the owners of these classic homes remodeled or refreshed interiors to better fit their family’s lives

Full Story

HOUZZ TOURSMy Houzz: Goodwill and Good Taste in a Grand Colonial

Welcoming the community for charity fundraisers and more, this Massachusetts home radiates graciousness

Full Story

REMODELING GUIDESHow People Upgrade Their Main Bathrooms, and How Much They Spend

The latest Houzz Bathroom Trends Study reveals the most common budgets, features and trends in master baths. Now about that tub …

Full Story

HOUZZ TOURSHouzz Tour: Traditional Sensibility Marks New ‘Not-So-Big’ House

An interior designer wanted her family's lakeside Minnesota farmhouse to emphasize quality over quantity

Full Story

LIFEHouzz Call: What’s Your Perfect House Size?

How big is too big? How small is too small? Please tell us which home size is just right for you

Full Story

SMALL SPACESCould You Live in a Tiny House?

Here are 10 things to consider if you’re thinking of downsizing — way down

Full Story

MOVINGWhy So Many New U.S. Homes Are Supersized

A bigger share of new homes sold in 2015 were 4,000 square feet or more compared with before the recession. But that could change

Full Story

LIFE10 Reasons to Love a Not-Big House

A smaller home is easier to maintain and furnish, and there are intangible benefits too

Full Story

SMALL SPACESLife Lessons From 10 Years of Living in 84 Square Feet

Dee Williams was looking for a richer life. She found it by moving into a very tiny house

Full StorySponsored

More Discussions

locknut

hayabusa

Related Discussions

Kubota GX 2100 vs John Deere X500

Q

Kubota pricing gr2100 or gr2000

Q

Kubota GR2110 Help

Q

Help me Compare the Kubota GR2000 to Simplicity AWD Conquest

Q

jswan101Original Author

hayabusa

jswan101Original Author

don21

jswan101Original Author

locknut

don21

morris07034

jswan101Original Author

zzzoro

paulk

jlangton

locknut

locknut

locknut

mownie

jswan101Original Author

locknut

locknut

jswan101Original Author

mownie

mownie

mownie

User

mownie

locknut

mownie

mownie

locknut

mownie

locknut

mownie

hilleyja

locknut