Hood FAQ

opaone

6 years ago

last modified: 6 years ago

Featured Answer

Comments (103)

D H

3 years agoopaone

3 years agoRelated Discussions

Range Hood FAQ + personal notes (updated 10/31/2007)

Comments (20)I hadn't seen this thread when it appeared in Oct. I actually find it kinda odd. The OP has never posted again. Maybe it was indeed spam? Either way, I have really found the original Range Hood FAQ very helpful, and have emailed the link to friends cause it's such a good summary. I don't think the OP has added anything helpful to the hood FAQ, and his additions might confuse someone new to the Appliances Forum, or someone struggling with hood choices (the hardest choice for me in my kitchen!). As others have pointed out, it's odd he chose a 36" hood for a 48" range. Odd that he doesn't mention Wolf hoods in his discussion of high-end hoods, even though that's the range brand he chose. Why does he say baffles are not standard in high-end hoods - that's incorrect. And indeed, despite his contention, the greater component of noise in a hood is the airflow. You can have two identical hoods in two homes - the home with the problematic ductwork (i.e. more bends, longer, or narrower) will be noisier despite the identical motors. I think the Futuro hoods are a good brand, judging by what others have enthusiastically written on the Gardenweb about them. But I hope that people looking for helpful info on hoods in general will look at the original Hood FAQ rather than the OP's additions....See MoreWhich style exhaust hood (insert, undercab, chimney is most effective?

Comments (15)What type of cooking do you do? Lots of grease? Lots of onions and garlic? Lots of deep frying? I've had downdrafts, custom hood with insert, regular over the stove microwave with direct vent to outdoors (outside wall) over a 30" gas stove. The Micro over stove directly vented to outdoors worked great (micro over stove not my favorite). The downdraft JennAir with grill and downdraft worked great. The custom hood with insert was my favorite aesthetically, and vented through the roof and worked fine. I don't fry a lot of foods (less as time goes on), virtually never deep fry, and use lids a lot because I don't think anything keeps the smell of frying onions contained (just my opinion). Downdrafts seems to get a lot of pushback but the one I had was terrific. I think you can have reasonable aesthetics, reasonable cost, and reasonable effectiveness :) though perhaps not great :) But though we cook a lot (if guessing, I'd say more than 85% of the population) and microwave very little, I have never felt the need for super-high power and I don't like lingering odors. If I were doing a new kitchen, I'd do a downdraft because I really lean towards clean lines and more modern interiors. So, the bottom line I think is to consider how you cook, and if you cook lots and lots of greasy and odiferous foods on a daily basis, super high power performance might outweigh anything else....See MoreCommercial Range Hood Install

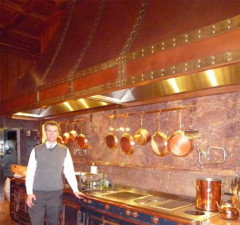

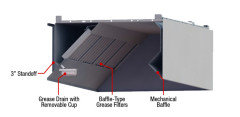

Comments (129)The original author no doubt has installed a type 1 hood with type 2 duct operating at type 1 capacity 1400cfm. Yes. I don't need full on commercial type 1. Per above we will not produce the amount of grease or smoke that requires a full type 1 system. HOWEVER, we like most residential, do need more than Type 2. We do produce some grease and smoke and some kind of baffle/filter is needed (or at least highly beneficial). The amount of stuff that I cleaned off our VAH and our current Accurex is a testament to that. So residential is perhaps realistically Type 1a (moderately heavy grease/smoke) and Type 1b (light grease/smoke) that are both less stringent requirements than full Type 1 (very heavy grease/smoke). Our need/desire for a commercial hood though had nothing to do with that but rather containment. Consumer hoods all have inadequate containment volume (as well as inadequate capture area). So really the only thing about this system that is 'commercial' is that I have a bigger empty box. We actually looked at using something like a Wolf and adding a 14" extension to the bottom of it to effectively increase its containment volume but in the end the cost to just have Accurex build a proper hood wasn't that much more expensive. That was my issue w/ the ignorance displayed by @Angela Bickford on numerous levels. A bigger empty box like ours does not create a need for greater MUA or greater exhaust CFM's but actually quite the opposite as having proper containment results in much better effectiveness with lower CFM's (which is what is really bad about consumer hoods not simply having proper containment volume). @catinthehat, as well as many others, actually have more rated CFM's than we do. Though we have a '1400 CFM blower' it is only used at 84% max or 1200 CFM but the larger blower is quieter at lower speeds and that is something that Accurex and CaptiveAire both do routinely to help reduce noise....See MoreExhaust Hood FAQ II

Comments (118)Well, I live in NH, and can provide some climate-relevant comments, at least if you live south of, say, Plymouth. I should note that my Wolf hood (actually built by Independent for Wolf in ca. 2008) is a 'Pro Island' model hood. I believe all of the Wolf hoods that are of the canopy type -- wall and island -- will be suitable for cooking ventilation if large enough and provided with sufficient flow rate. I have no other styles of Wolf hood to directly evaluate. For those who have reached this point via tl;dr, a brief summary follows without much justification. First, it is necessary to determine requirements and then select among candidate hood systems that meet those requirements. For capture of rising and expanding cooking plumes, the canopy has to overlap the plumes at the height of the canopy. For 36-in hood base hight over the counter, this is about 3 inches wider than the cooktop, as well as deeper. For containment of hot cooking -- defined here as hot oils at the smoke point, searing, wok cooking, and other combined moisture/grease plume producing cooking -- an air velocity at the hood base of about 90 ft/min is desirable with residential style canopy hoods with small volumes in the reservoir space below the baffles. This directly implies 90 CFM/sq. ft. Typical blowers in typical pressure loss operating conditions will likely move only about 2/3 of their rated (zero static pressure) flow rate. So, take the intake area, multiply by 90, further multiply by 1.5, and the result should be in the ballpark of the required rated blower flow rate (CFM). This is likely to be higher than 400 CFM. Cooking content, induction vs. gas, and other factors may allow some reduction of the calculated requirement, while poor MUA can increase the rated requirement, but I wouldn't drop very much if you want to ensure clean interior air and no grease on the house surfaces. Duct size should limit full power air flow to between 1000 and 2000 ft/min. No air is removed from the kitchen that isn't resupplied. Insufficient supply just causes the blower to move less air. The resupply is called make-up air (MUA), and it can be deliberate or accidental (through the walls, say). Deliberate MUA can be passive (no blower) or active (with blower). Accidental is undesirable for many reasons, and just because there is a limit at 400 rated CFM doesn't mean MUA should be ignored. How well the MUA needs to keep the kitchen pressure close to that of the exterior air depends on presence or not of combustion appliances that can be back-drafted at some household pressure. Back-drafting is hazardous. So by example 42 x 27 is 7.9 sq. ft. calling for about 700 actual CFM and around a 1000 CFM rated blower. In a 10-inch duct, 700 CFM has a velocity of 1200 ft/min, so I would not go smaller. Also, please note that with a roof damper and a damper above the hood, minimal cold air will be drawn into the house when the blower is off. I space allows, a silencer (Fantech LD-10 for example) can be placed between hood and blower for a considerable reduction in noise. If you use passive MUA because of lack of combustion appliances, you will not be able to run the fireplace when the blower is operating at higher flow rates. For this an active MUA is needed, such as Fantech makes. _________ P.S. A house as large as the Pentagon would eventually drop in pressure with an externally vented hood unless air was replaced. House size doesn't matter except for providing more leakage paths that you should avoid using. P.P.S. Wolf answers their phones and provides technical data. Otherwise, they are one of no doubt many suppliers of quality hoods that can provide good capture and containment when properly specified. For example, I strongly suspect that ModernAire knows what they are doing, even though I have never seen one of their hoods in person. Similarly, ABBAKA, to name two....See Morekaseki

3 years agoopaone

3 years agoopaone

3 years agokaseki

3 years agolast modified: 3 years agoopaone

3 years agolast modified: 3 years agoopaone

3 years agokaseki

3 years agolwfromny

3 years agoAglitter

3 years agokaseki

3 years agolwfromny

3 years agoMichael

3 years agoopaone

3 years agolast modified: 3 years agokaseki

3 years agoopaone

3 years agolast modified: 3 years agoopaone

3 years agoTheana Angelus

3 years agokaseki

3 years agoAglitter

3 years agoAglitter

3 years agoc9pilot

3 years agobilly_g

3 years agokaseki

3 years agolast modified: 3 years agoopaone

3 years agolast modified: 3 years agobilly_g

3 years agoAglitter

3 years agolast modified: 3 years agoopaone

3 years agobilly_g

3 years agobilly_g

3 years agokaseki

3 years agobilly_g

3 years agoopaone

3 years agokaseki

3 years agobilly_g

3 years agoopaone

2 years agobilly_g

2 years agoopaone

2 years agolast modified: 2 years agobilly_g

2 years agobilly_g

2 years agobilly_g

2 years agoopaone

2 years agobilly_g

2 years agoN

2 years agoAglitter

2 years agolast modified: 2 years agoopaone

2 years agoLauren

7 months agoAglitter

7 months ago

Related Stories

KITCHEN DESIGNWhat to Know When Choosing a Range Hood

Find out the types of kitchen range hoods available and the options for customized units

Full Story

KITCHEN APPLIANCESDisappearing Range Hoods: A New Trend?

Concealed exhaust fans cut visual clutter in the kitchen

Full Story

KITCHEN WORKBOOKHow to Remodel Your Kitchen

Follow these start-to-finish steps to achieve a successful kitchen remodel

Full Story

ARCHITECTUREAre Vaulted Ceilings Right for Your Next Home?

See the pros and cons of choosing soaring ceilings for rooms large and small

Full Story

DECORATING GUIDESA Mobile Home Gets a Bohemian-Chic Makeover

Designer infuses world traveler’s guesthouse with tribal textiles, Moroccan tiles and kilim rugs

Full Story

MOST POPULARPros and Cons of 5 Popular Kitchen Flooring Materials

Which kitchen flooring is right for you? An expert gives us the rundown

Full Story

FURNITUREOrigins Revealed: The Orkney Chair Goes From Humble to Haute

Straw and driftwood made up the original versions, but Orkney chairs have come a long way from their modest island beginnings

Full Story

MOST POPULAR33 Magic Household Cleaning Tips

Houzzers from around the world share their tips for transforming housework into child’s play

Full Story

KITCHEN DESIGN10 Ideas for a Breezy Coastal Kitchen

Go for nautical details and sea-inspired colors to create a beautifully beachy space

Full Story

kaseki