Support Beams

eam44

8 years ago

Featured Answer

Sort by:Oldest

Comments (24)

Related Discussions

smooth finish for interior concrete support beam

Comments (6)Thanks Rockin’ Fine Finish. I tried Sakrete pre-mixed concrete patch and it is quite sandy. See photo. Is there a particular concrete patch that you can send a link for? I checked both companies and both seem to have a sandy composition....See MoreAdvise please..Support beam in basement

Comments (14)All the splices that you see must be over the bearing points. You have to replace the lolly columns, the one they use (or if there is more) the one in the picture doesn't belong there. You need a licensed framing crew to replace the existing beam and install new lolly columns, they will know what to do, this can be done fairly quick you just need a contractor specializing in framing. Whoever did the work there didn't know what they were doing and they botched everything up. P.S. I wouldn't plan to have any parties or too many people at the house, because you don't want to have that floor loaded more than it should be, this has to be fixed right away, because if that beam gives for whatever reason, the middle of the house will cave-in....See MoreLoft bed needs curtains but support beam is the way

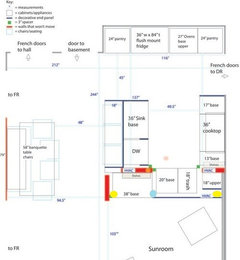

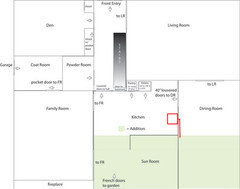

Comments (1)Maybe a search along this line?...See MoreComplete design flaw! Arched Support beam + Kitchen wall

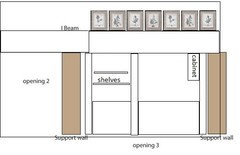

Comments (9)It could be years before a remodel, you know how it goes, life gets in the way. Drywall's cheap. This is what I was meaning: RED is infill in the arch plane. BLUE is infill on the sides of posts. GREEN is infill on the angled wall plane as it looks like there is a silly recess there too. YELLOW is optional extend angled wall up to ceiling, but there is another silly notch there to complicate the cleanliness of lines. I also notice there is that short wall blocking the window (with the picture hanging), that looks like you can't walk behind it. In the future fix that along with the angled kitchen footprint....See Moreeam44

8 years agoeam44

8 years agolast modified: 8 years agoeam44

8 years agolast modified: 8 years agozmith

8 years agoeam44

8 years agolast modified: 8 years agoeam44

8 years agoeam44

8 years agolast modified: 8 years agoeam44

8 years agolast modified: 8 years agoeam44

8 years ago

Related Stories

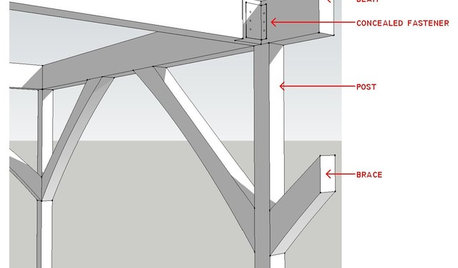

REMODELING GUIDESSupporting Act: Exposed Wood Trusses in Design

What's under a pitched roof? Beautiful beams, triangular shapes and rhythm of form

Full Story

KITCHEN DESIGNOpening the Kitchen? Make the Most of That Support Post

Use a post to add architectural interest, create a focal point or just give your open kitchen some structure

Full Story

DESIGN DICTIONARYBeam

This horizontal piece of wood or steel gives support to a home's architecture

Full Story0

DESIGN DICTIONARYOpen Web Steel Joist

Give your roof or floor a support network, woven between the beams

Full Story0

DESIGN DICTIONARYHeader

Wide openings get the support they need from this stalwart horizontal beam

Full Story0

REMODELING GUIDESKnow Your House: Post and Beam Construction Basics

Learn about this simple, direct and elegant type of wood home construction that allows for generous personal expression

Full Story

DESIGN DICTIONARYPost and Lintel

When horizontal beam meets post, the combination pulls its weight in a home

Full Story

HOUZZ TOURSMy Houzz: Neo-Barbarian Style in Ohio

Eccentric artwork, open beams and whimsical touches define this custom-built home

Full Story

DESIGN DICTIONARYSteel Girder

This framing element is strong enough to support floors, roofs, catwalks and more in a single bound

Full Story0

Sponsored

Your Custom Bath Designers & Remodelers in Columbus I 10X Best Houzz

Joseph Corlett, LLC