K46 oil change with pictures

leafeanator

8 years ago

Featured Answer

Comments (69)

lkbum_gw

4 years agoleafeanator

4 years agolast modified: 4 years agoRelated Discussions

Scotts Tuff Torq K46 Transmission

Comments (3)The K46 does have serviceable seals and axle bushings, I believe the seal is driven in rather than being retained by a lip in the housing. You should be able to tell by cleaning the area up and having a look. If it is an active leak rather than a light seep, it should be attended to sooner rather than later. If not sure, clean it up and watch it. No leaks are obviously better than having one. Plus, you get the opportunity to change the oil....See MoreTuff Torq K46V

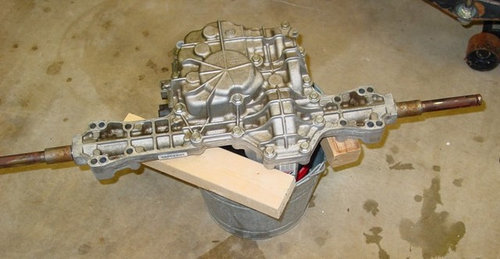

Comments (0)I was having a lot of trouble with my lawn tractor losing power. I decided to find out why. After doing a little searching on the internet I found that I needed to change the oil in it. When I pulled out the sealer cap and the removing the magnet I found gritty sludge stuck to the magnet. I decided to take my transmission apart and clean it out real good. Everything went well untill I started to put it back together. The hydraulic pumps inside are a devil to reasemble. Especialy the one driven by the pully shaft on top of the tranny. I found out also that it has TWO magnets and a small filter inside. The filter was really dirty. There are two small steel balls inside that are really easy to lose. If anyone takes they'rs apart like I did be very carefull not to lose them. I got my tranny all put back together now and am waiting for a new sealer cap and vent. I had to order those. I am writing this to let folks know that sometimes just changine the oil may not be enough. You might have to do what I did and give it a good cleaning out. Especialy that fiber filter. It gets full of grit and sludge. I don't recomend disasembling the pump housing at all. I lost one of the tiny steel balls. Lucky for me I had another one. The upper rotary pump (the one driven by the pully shaft ) is very hard to reasemble....See MoreJD X300 transmission failure

Comments (46)my2014 X300 transmission just died.,.,,.230 hrs on it.,.,i mow approx. 1.2 acres and use the 44 inch snowblower.,.,.,i was told by dealer that J.d new of this transmission issue early on and then rebuilt/redesigned the tranny in the newer versions in 2018.,.,realizing that the 3/4 axles were borderline strong enough for the snowblower attachment.,.,.,$1,200 later.,.,i'm mowing again.,.,,.if your going to add attachment to any tractor maybe 3/4 axle should be avoided.,...See MoreK46 oil change notes

Comments (18)there is minor play in two directions an mine . pulley moves up and down along shaft a small amount, due to normal looseness from use of a spring spacer in that assembly. separately there is side to side play allowing pulley to rotate on shaft slightly before splines on shaft are fully engaged. I would expect a pulley to fit snugly onto the splined shaft since leaving it loose will encourage accelerated wear of splines. Interestingly, there is a similar amount of rotational play with the plastic fan on the same shaft. That seems to suggest that there was some play in both pulley and fan on shaft from new, since by now the pulley would have seen a lot more force and wear than fan. It was the fact that there was some play in both fan and pulley that prompted my original question to see if when new there would have been no play or if a little was normal....See Morelkbum_gw

4 years agobradkennedy

4 years agoleafeanator

4 years agolast modified: 4 years agobradkennedy

4 years agoshadetree123

4 years agoleafeanator

4 years agolast modified: 4 years agobradkennedy

4 years agossewalk1

4 years agoleafeanator

4 years agotomplum

4 years agossewalk1

4 years agoPaul Welford

3 years agoleafeanator

3 years agoPaul Welford

3 years agoGavin Cox

3 years agoleafeanator

3 years agolast modified: 3 years agoGavin Cox

3 years agolkbum_gw

3 years agolast modified: 3 years agoGavin Cox

3 years agolkbum_gw

3 years agoGavin Cox

3 years agoBrad Thornell

3 years agoleafeanator

3 years agotoxcrusadr

3 years agolast modified: 3 years agoleafeanator

3 years agotoxcrusadr

3 years agoRay Jennings

3 years agoleafeanator

3 years agohammondbaptist

3 years agoleafeanator

3 years agochris chris

3 years agoleafeanator

3 years agochris chris

3 years agohammondbaptist

3 years agochris chris

3 years agomynutsrturning

3 years agochris chris

3 years agoleafeanator

3 years agolast modified: 3 years agochris chris

3 years agoleafeanator

3 years agochris chris

3 years agochris chris

3 years agoleafeanator

3 years agolast modified: 3 years agochris chris

3 years agoHU-121587230

last yearHU-416950076

10 months ago

Related Stories

FURNITUREMeet the Quick-Change Artists of Interior Design

Are you missing a great little stool, ottoman or bench? Just look at the ways they can adapt to what you need now

Full Story

GREAT DESIGNERSThe Controversial House ‘That Changed the Way We Live’

A rivalry with Le Corbusier nearly ruined Irish designer Eileen Gray’s career, but 2 new films celebrate her as ‘the mother of modernism’

Full Story

BOOKSCan Tidying Up Result in Life-Changing Magic?

Organizing phenom Marie Kondo promises big results — if you embrace enormous changes and tough choices

Full Story

LIFEStop the Toy Takeover by Changing the Way You Think

Make over your approach and get gift givers onboard with your decluttering efforts by providing meaningful toy alternatives

Full Story

DECORATING GUIDESSmall Changes to Simplify Your Long-Term Storage

Conquer your attic and basement storage in more than a day, with these easy, bite-size steps for sorting, storing and protecting your stuff

Full Story

BEDROOMSRoom of the Day: Parents-to-Be Ready Their Bedroom for Change

A renovated bedroom and loft make room for middle-of-the-night feedings and quiet time

Full Story

COMMUNITYGet a Bird's-Eye View of America's Housing Patterns

See the big picture of how suburban developments are changing the country's landscape, with aerial photos and ideas for the future

Full Story

DECORATING GUIDESConquer That Blank Wall With a Versatile Picture Ledge

Turn a dull spot into your own personal art gallery with shallow shelves displaying artwork you can swap out on a whim

Full Story

KITCHEN DESIGNShow Us Your Compact Kitchen

Do you have a tiny kitchen that works well for you? Post your pictures in the Comments

Full Story

KITCHEN DESIGN12 Great Kitchen Styles — Which One’s for You?

Sometimes you can be surprised by the kitchen style that really calls to you. The proof is in the pictures

Full Story

John Macek