Disadvantages of roof trusses?

athensmomof3

13 years ago

Featured Answer

Sort by:Oldest

Comments (21)

brickeyee

13 years agolast modified: 9 years agoathensmomof3

13 years agolast modified: 9 years agoRelated Discussions

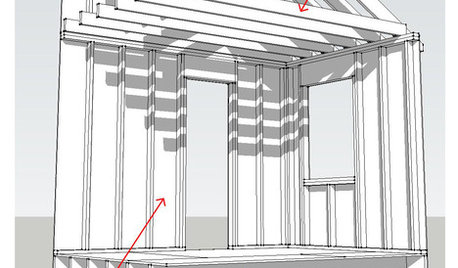

roof trusses before interior walls?

Comments (8)We just recently built a house owner/builder. Our interior walls were up before the trusses, but like PPF stated above, the trusses sat on the exterior walls for support and didn't need the interior walls. That said, I designed the house to have a very simple roof. If you have a complicated roof, you might have some interior bearing walls which means some of your trusses have to sit on the interior walls for support. The other problem could be that due to the current building boom, truss manufactures are really busy. Last year, our trusses were almost 4 weeks delayed. I think this year things are worse....See MoreWhich roof plan is best? And stick built or Truss?

Comments (29)Just a comment from someone living in a hipped roof house. It is very limiting if one wants to add solar panels (and in my case this is an old house that did not have the attic ventilated and there are no vertical faces to install vents in- it will be difficult without breaching the roof). I'm not sure of the advantage, guess for looks only? I suppose less wind-resistance and good plan for tornado country. Another observation about all the dormers and different facets, including valleys. In snow country, could cause problems as snow hangs up in the valleys. I suppose if money is no object (as in richy rich) you will always have someone around to respond to problems in the future. Last thing, I believe in simplicity, metal roofs, shedding water asap and guttering it away from the structure. Water will win the battle in the end....See MoreCost to raise ceilings while re-trussing a damaged attic/roof?

Comments (12)A gable roof where the ridge sagged has also pushed out on the walls. So demo roof/ceiling. Ceiling joists stay or go, repair or add. Electrical in ceiling if go. If stay then siding because truss sits higher. Shore/plumb walls. Trusses, sheathing/shingles. Gutters, fascias, soffits. Misc HVAC/plumbing (vents, exhaust, attic ductwork). Ceiling finish. Insulation. Rewire, probably new circuits and lighting fixtures. Can of worms and project creep unaccounted for. WAG $80K DIY --> $150K contracted, 12 weeks pandemic ignored....See MoreRoof truss and lumber help please!

Comments (10)Ontario building codes does reference different grades of lumber for different building applications with the exception to Trusses. In this case it's refers to loads and deflection minimums and references to ATSM standards used for certification. I would take this as to say no grade is specified in code for trusses but will be determined by engineered design to meet minimum requirements in the code through ATSM standards. So they could make the trusses out of pop sickle sticks if engineered to meet the minimum requirement of the code through ATSM testing standards. So it doesn't matter if they use MSR or grade 2 and why the two truss companies use different grades. Both will have the desired outcome when engineered and both acceptable to use, so it could be just based on the preference of the material the two companies elect to use. One grade over the other may not be compatible with their software design program or truss jigs and could be just be a matter of economics to support both grades of lumber to build the trusses....See Morejuniork

13 years agolast modified: 9 years agoEpiarch Designs

13 years agolast modified: 9 years agobuckheadhillbilly

13 years agolast modified: 9 years agofish7577

13 years agolast modified: 9 years agoworthy

13 years agolast modified: 9 years agoathensmomof3

13 years agolast modified: 9 years agobrickeyee

13 years agolast modified: 9 years agoworthy

13 years agolast modified: 9 years agonini804

13 years agolast modified: 9 years agobrickeyee

13 years agolast modified: 9 years agoEpiarch Designs

13 years agolast modified: 9 years agobrickeyee

13 years agolast modified: 9 years agoworthy

13 years agolast modified: 9 years agoworthy

13 years agolast modified: 9 years agoUser

13 years agolast modified: 9 years agobrickeyee

13 years agolast modified: 9 years agosombreuil_mongrel

13 years agolast modified: 9 years agobrickeyee

13 years agolast modified: 9 years ago

Related Stories

REMODELING GUIDESSupporting Act: Exposed Wood Trusses in Design

What's under a pitched roof? Beautiful beams, triangular shapes and rhythm of form

Full Story

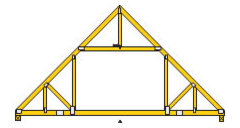

ARCHITECTURELearn the Language of Trusses in Design

If figuring out all those intersecting beam configurations under roofs makes your eyes cross, here's help

Full Story

DESIGN DICTIONARYTruss

To figure out exactly how strong these roof braces are, you'll need to do the math

Full Story0

KNOW YOUR HOUSEKnow Your House: Components of a Roof

Don't get held up by confusion over trusses, rafters and purlins. Learn about a roof's features and their purposes here

Full Story

ROOFSWhat to Know Before Selecting Your Home’s Roofing Material

Understanding the various roofing options can help you make an informed choice

Full Story

ROOFSRoof Materials: Get an Old-World Look With Clay Roof Tiles

The ancient roof material of choice remains the modern-day ideal for authentic Italian, Mediterranean and Spanish home styles

Full Story

EXTERIORSRoofing Materials: Slate Makes for Fireproof Roofs That Last

It stands up to weather and fire without losing its high-end look. But can your budget handle it?

Full Story

REMODELING GUIDESMaterials: The Advantages of a Metal Roof

Metal reigns in roofing style, maintenance and energy efficiency

Full Story

EXTERIORSRenovation Detail: The Gambrel Roof

With sloped sides rising to a graceful center point, the classic gambrel roof combines architectural beauty and interior breathing room

Full Story

ROOFSNo Substitute for the Natural Beauty of Wooden Roof Shingles and Shakes

This natural, renewable roof option brings weathered character and nostalgic appeal to traditional-style homes

Full Story

User