john deere stx38 pto switch shuts off engine

BarryBob

11 years ago

Featured Answer

Sort by:Oldest

Comments (6)

javert

11 years agoRelated Discussions

deere stx38 pto switch

Comments (2)Thanks to javert's posting above I saved a whole bunch on repairs for my STX38. My clutch would not engage so I pulled the connector to the clutch to see how much voltage was getting to it. Found I only had between 5 and 8 volts. One of the two wires going to the clutch is a ground wire going to the frame just above the clutch and was heavily corroded. Took out the ground bolt and cleaned everything with steel wool, put it back together and had a strong 12 volts. Works like new. Total cost about 1 hour of my time. Thank you very much!...See Morejohn deere stx38 pto wont engage

Comments (32)Hey folks, so I'm posting this follow up in my original thread because I think I have a related problem. Last year, I replaced the PTO drive belt and the mower blade drive belts on my inherited JD STX 38 Yellow Deck. Today I took the mower out (NOT the first time this season) and had some serious issues. First of all, the grass is tall - 18-24 inches. I had the mower height set to the tallest height. The grass may have also been slightly damp - although not wet. I was able to cut basically one path, then I realized that although the PTO was engaged, the blades weren't cutting the grass. I was going at the slowest speed (first gear) and even tried cutting using only 1/2 of the mower deck width at a time - no help. I took the mower back to my driveway, cleared out lots of old clumped grass from the blades, and started the mower and the PTO. The blades were definitely turning. I turned off the mower again, and noticed that the PTO drive belt is looking terrible - it's all pitted and slack - it's not tight around the PTO shaft! So, my theory is this: the PTO drive belt is shot again (Although not broken yet) - so the blade spin when I'm not trying to cut anything, but when I come in contact with any sort of grass of substance, the slack belt is "slipping" and resulting in the blades not cutting? Does this make sense? Solution: replace the belt AGAIN???? A few more things to note: 1) I tried cutting shorter grass and drier grass and had very little luck. 2) why would my PTO drive belt, just replaced a year ago, be so shredded already? That's worrisome... any advice would be appreciated. thanks....See MoreJohn Deere STX-38...fuel starvation????

Comments (3)(1) Disconnect tank outlet line to check for a strong fuel flow. Loosen cap.Blow air through the inlet line into gas tank,if slow.(2) If OK, Install (solder) a brass hose fitting in a gallon metal can to make a temporary fuel tank.Put ths 'tank' on top of tractor,and run a fuel line from it to the carb inlet.Add about a qt of fuel.Run engine.This can help pinpoint the problem area,if a fuel delivery problem....See MoreSTX-38 John Deere won't start

Comments (15)Best that you test the wire at the PTO clutch connector for voltage when the PTO switch is turned on. Do this with the key on, engine NOT RUNNING. If you do not have voltage at the clutch when the PTO is turned on, your PTO switch may be bad or there could be a broken wire between the PTO switch and the PTO clutch. If you DO HAVE voltage at the PTO clutch wire connector but the PTO clutch will not engage.......your PTO clutch has likely failed. You might even get lucky and find that wire broken or unplugged....See MoreBarryBob

11 years agobill_kapaun

11 years ago89tango

10 years ago89tango

10 years ago

Related Stories

DISASTER PREP & RECOVERYMore Power to You: How to Pick the Right Generator

If your home's electricity goes, don't let it take your necessities with it — keep systems running with this guide to backup power

Full Story

BEDROOMSDream Spaces: Bedrooms With Amazing Views

Soaring over the city or nestled amidst nature, these sleeping spaces focus on the most divinely designed feature of all

Full Story

LIFEHouzz Call: How Are You Handling the Record-Breaking Cold?

Share your tales, strategies and photos for everything polar vortex

Full Story

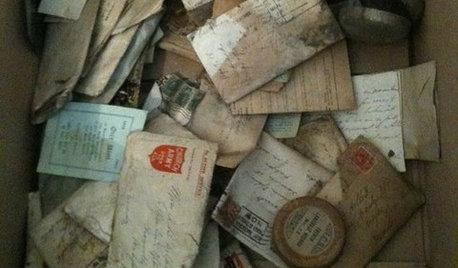

REMODELING GUIDESYou Won't Believe What These Homeowners Found in Their Walls

From the banal to the downright bizarre, these uncovered artifacts may get you wondering what may be hidden in your own home

Full Story

CONTRACTOR TIPSBuilding Permits: 10 Critical Code Requirements for Every Project

In Part 3 of our series examining the building permit process, we highlight 10 code requirements you should never ignore

Full Story

CURB APPEALHouzz Call: How Do You Hide Your Trash?

No one wants to see those trash and recycling bins. So where do you stash them while you wait for the garbage truck? Show us your designs!

Full Story

sswinehart