DYT 4000 won't start, how much damage did my brother do?

new2lawncare

15 years ago

Related Stories

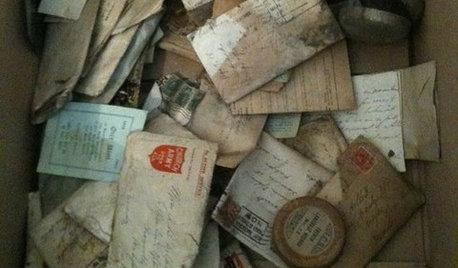

REMODELING GUIDESYou Won't Believe What These Homeowners Found in Their Walls

From the banal to the downright bizarre, these uncovered artifacts may get you wondering what may be hidden in your own home

Full Story

REMODELING GUIDESFollow a Ranch House Renovation From Start to Finish

Renovation Diary, Part 1: Join us on a home project in Florida for lessons for your own remodel — starting with finding the right house

Full Story

HOUZZ TOURSHouzz Tour: New Love and a Fresh Start in a Midcentury Ranch House

A Nashville couple, both interior designers, fall for a neglected 1960 home. Their renovation story has a happy ending

Full Story

KITCHEN DESIGNStylish New Kitchen, Shoestring Budget: See the Process Start to Finish

For less than $13,000 total — and in 34 days — a hardworking family builds a kitchen to be proud of

Full Story

MOST POPULAR10 Things to Ask Your Contractor Before You Start Your Project

Ask these questions before signing with a contractor for better communication and fewer surprises along the way

Full Story

CONTRACTOR TIPS10 Things to Discuss With Your Contractor Before Work Starts

Have a meeting a week before hammers and shovels fly to make sure everyone’s on the same page

Full Story

DESIGN PRACTICEDesign Practice: Start-up Costs for Architects and Designers

How much cash does it take to open a design company? When you use free tools and services, it’s less than you might think

Full Story

DECLUTTERINGDecluttering — Don't Let Fear Hold You Back

Sure, you might make a mistake when tackling a decluttering project, but that's OK. Here's why

Full Story

LIFEHow to Handle Inherited Things You Don’t Really Want

Whether you’ve inherited a large collection of items or a single bulky piece of furniture, it’s OK to let it go if you don’t need or want it

Full Story

FUN HOUZZ10 Things People Really Don’t Want in Their Homes

No love lost over fluorescent lights? No shocker there. But some of these other hated items may surprise you

Full StorySponsored

new2lawncareOriginal Author

bill_kapaun

Related Discussions

my 14.5 HP briggs won't start

Q

Sears DYT4000 2004 Smoke Cloud...

Q

briggs & stratton won't start too much compression

Q

craftsman dyt 4000

Q

new2lawncareOriginal Author

larryf

new2lawncareOriginal Author

bill_kapaun

rustyj14

rcmoser

new2lawncareOriginal Author

bill_kapaun

new2lawncareOriginal Author

rcmoser

new2lawncareOriginal Author

bill_kapaun

rcmoser

mownie

new2lawncareOriginal Author

bill_kapaun

new2lawncareOriginal Author

bill_kapaun

rcmoser