6 x 8 HF Greenhouse Question

cugal

11 years ago

Related Stories

MOST POPULAR8 Questions to Ask Yourself Before Meeting With Your Designer

Thinking in advance about how you use your space will get your first design consultation off to its best start

Full Story

GREEN DECORATING8 Questions to Help You See Through Green Hype

With the ecofriendly bandwagon picking up some dubious passengers, here's how to tell truly green products and services from the imposters

Full Story

GARDENING AND LANDSCAPINGSee a Family Greenhouse Grown From Scraps

Can-do resourcefulness and less than $400 lead to a new 8- by 8-foot home for plants on a Tennessee family's property

Full Story

KITCHEN DESIGN9 Questions to Ask When Planning a Kitchen Pantry

Avoid blunders and get the storage space and layout you need by asking these questions before you begin

Full Story

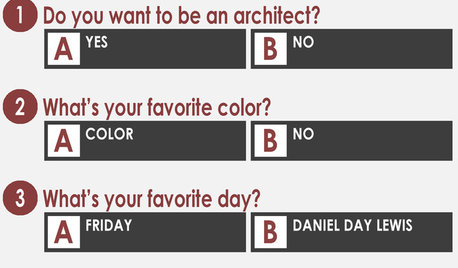

COFFEE WITH AN ARCHITECTA Quiz for Architects in Question

Should you trade in your T-square for a barista tray? Answer a few simple questions to find out

Full Story

DOORS5 Questions to Ask Before Installing a Barn Door

Find out whether that barn door you love is the right solution for your space

Full Story

LIGHTING5 Questions to Ask for the Best Room Lighting

Get your overhead, task and accent lighting right for decorative beauty, less eyestrain and a focus exactly where you want

Full Story

REMODELING GUIDES9 Hard Questions to Ask When Shopping for Stone

Learn all about stone sizes, cracks, color issues and more so problems don't chip away at your design happiness later

Full Story

MOVINGHiring a Home Inspector? Ask These 10 Questions

How to make sure the pro who performs your home inspection is properly qualified and insured, so you can protect your big investment

Full Story

MichiganFarmer

gltrap54

Related Discussions

hfgh 8x6 greenhouse questions

Q

HF 8x6 insulation & vents

Q

Exhaust fan for HF 6X8

Q

Tent woodstove for 6x8 HF Greenhouse

Q

mudhouse_gw

cugalOriginal Author

mudhouse_gw

cugalOriginal Author

poaky1

mudhouse_gw

saturn3600

poaky1

hartford

rodco

mudhouse_gw

eastpenna

Textea

poaky1

poaky1

mudhouse_gw

poaky1

mudhouse_gw

poaky1

saturn3600

mudhouse_gw

poaky1

mudhouse_gw